Full Cocoa Bean Powder Processing Plant 3-5 TPD

- Material: Cocoa Beans

- Capacity: 3-5 T Per Day

- Loading Port:Qingdao Port

- Warranty:12 Months

- Quote Form:FOB, CIF, EXW, CFR

Features

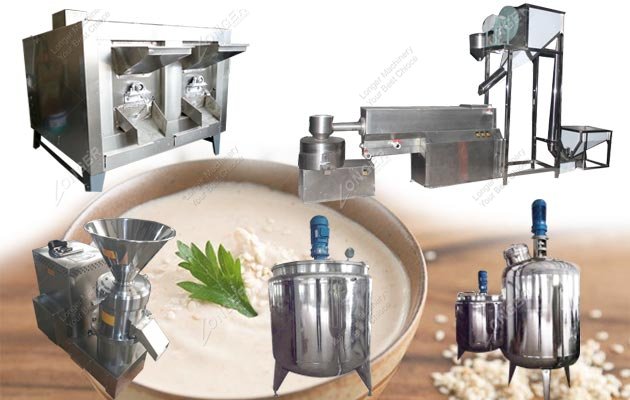

This full cocoa bean processing plant can complete the production of cocoa nibs, cocoa liquor, cocoa butter and cocoa powder with highly automated equipment, high efficiency and reduced labor costs. We can provide you with customized complete solutions according to your factory layout.

Cocoa Bean Processing Flow:

Cocoa Bean Cleaning ---- Roasting ---- Cooling ---- Peeling ---- Grinding ----Oil Pressing ---- Powder Grinding ---- Packing

Equipment in a Cocoa Powder Processing Plant:

1. Cocoa Bean Roaster Machine

Roasting is the most important step in cocoa processing. First, roasting can decompose the acidic substances in cocoa beans and reduce the sour taste of cocoa. Second, high temperature can kill bacteria on the surface of the material, making it safer to eat. Third, the roasted and cooled cocoa beans become crispy and easy to peel.

In the continuous cocoa powder production line, we have designed two kinds of roasting machines, one is a belt roasting machine, and the other is a roasting and cooling integrated machine. If your output is not large, you can choose a belt roaster. If your production capacity is 5-10 tons per day, you can choose an all-in-one machine with higher roasting efficiency.

2. Cocoa Bean Crushing and Peeling Machine

The roasted cocoa beans cannot be directly put into the grinding machine. They need to be peeled and broken to form small particles of cocoa nibs.

To this end, our peeling machine can achieve this purpose very well. Through the extrusion inside the machine, the vibration of the conveyor net, and the suction of the air separator, 99% of the cocoa beans are peeled.

3. Cocoa Grinding Machine

The colloid mill can superfinely pulverize cocoa nibs in a very short time, that is, micronization has the functions of mixing, stirring, dispersing and emulsifying at the same time. The grinder produced by us can produce fine and smooth cocoa paste with only about 0.15mm particles.

4. Cocoa Butter Press Machine

Next is the pressing of cocoa butter. We produce a hydraulic oil press, the pressing pressure can reach 60Mpa, and within 10 minutes, the oil content in the cocoa cake can reach about 12%. One of the advantages of hydraulic oil pressing is that the temperature will not rise during processing, and the nutrients in the material will not be damaged due to high temperature.

5. Cocoa Powder Making Machine

The pressed cocoa cake is very hard and cannot be easily ground, so we have to go through two steps - coarse crushing and fine grinding to obtain fine quality cocoa powder.

Our grinders are made of high-quality carbon steel as a whole, which is solid and durable. The design speed of the pendulum inside the machine can reach 3800r/min. Cocoa powder with different particle sizes can be obtained through a screen with adjustable mesh, and the fineness of the finished product is 80-100 mesh.

Cocoa Bean Processing Flow:

Cocoa Bean Cleaning ---- Roasting ---- Cooling ---- Peeling ---- Grinding ----Oil Pressing ---- Powder Grinding ---- Packing

Equipment in a Cocoa Powder Processing Plant:

1. Cocoa Bean Roaster Machine

Roasting is the most important step in cocoa processing. First, roasting can decompose the acidic substances in cocoa beans and reduce the sour taste of cocoa. Second, high temperature can kill bacteria on the surface of the material, making it safer to eat. Third, the roasted and cooled cocoa beans become crispy and easy to peel.

In the continuous cocoa powder production line, we have designed two kinds of roasting machines, one is a belt roasting machine, and the other is a roasting and cooling integrated machine. If your output is not large, you can choose a belt roaster. If your production capacity is 5-10 tons per day, you can choose an all-in-one machine with higher roasting efficiency.

2. Cocoa Bean Crushing and Peeling Machine

The roasted cocoa beans cannot be directly put into the grinding machine. They need to be peeled and broken to form small particles of cocoa nibs.

To this end, our peeling machine can achieve this purpose very well. Through the extrusion inside the machine, the vibration of the conveyor net, and the suction of the air separator, 99% of the cocoa beans are peeled.

3. Cocoa Grinding Machine

The colloid mill can superfinely pulverize cocoa nibs in a very short time, that is, micronization has the functions of mixing, stirring, dispersing and emulsifying at the same time. The grinder produced by us can produce fine and smooth cocoa paste with only about 0.15mm particles.

4. Cocoa Butter Press Machine

Next is the pressing of cocoa butter. We produce a hydraulic oil press, the pressing pressure can reach 60Mpa, and within 10 minutes, the oil content in the cocoa cake can reach about 12%. One of the advantages of hydraulic oil pressing is that the temperature will not rise during processing, and the nutrients in the material will not be damaged due to high temperature.

5. Cocoa Powder Making Machine

The pressed cocoa cake is very hard and cannot be easily ground, so we have to go through two steps - coarse crushing and fine grinding to obtain fine quality cocoa powder.

Our grinders are made of high-quality carbon steel as a whole, which is solid and durable. The design speed of the pendulum inside the machine can reach 3800r/min. Cocoa powder with different particle sizes can be obtained through a screen with adjustable mesh, and the fineness of the finished product is 80-100 mesh.

Technical Data

| No. | Name | Power(kw) | Dimension (mm) | Qty(set) |

| 1 | Destoning Machine with Pipe and Fan | 0.55+3 | 1350*1050*2950 | 1 |

| 2 | Metal separator | 0.01 | 700*700*1550 | 1 |

| 3 | Continuous Roasting Machine(Electric) | 63 | 11000*1440*1900 | 1 |

| 4 | Cooling Line | 5.15 | 5000*1250*1600 | 1 |

| 5 | Cocoa Bean Peeling Machine | 3 | 2000*800*2200 | 1 |

| 6 | Picking Line | 0.75 | 6000*800*1200 | 1 |

| 7 | Cocoa Liquor Grinding Machine | 15 | 1100*550*1100 | 1 |

| 8 | Storage Tank with cover | / | 650*650*450 | 1 |

| 9 | Cocoa Butter Press Machine | 3+4 | 1100*1100*1500 | 2 |

| 10 | Cocoa Cake Crushing Machine | 5.5 | 1000*700*1260 | 1 |

| 11 | Cocoa Powder Grinding Machine | 5.5 | 1350*700*1700 | 1 |

| 12 | Powder Packing Machine | 1.1+0.37 | 2200* 1100 * 3000 | 1 |

Related Products