Automatic Almond Shelling Line Processing Equipment 300-500 kg/h

- Material: Almond Nuts

- Capacity: 300-500 kg/h

- Loading Port:Qingdao Port

- Warranty:12 Months

- Quote Form:FOB, CIF, EXW, CFR

Features

The automatic almond shelling line is mainly used for shelling and separating almond hard shells of various specifications. They have the advantages of clean shelling, high integrity and durability. They are ideal equipment for automatic production in almond processing plants.

Working Principle of Almond Processing Line:

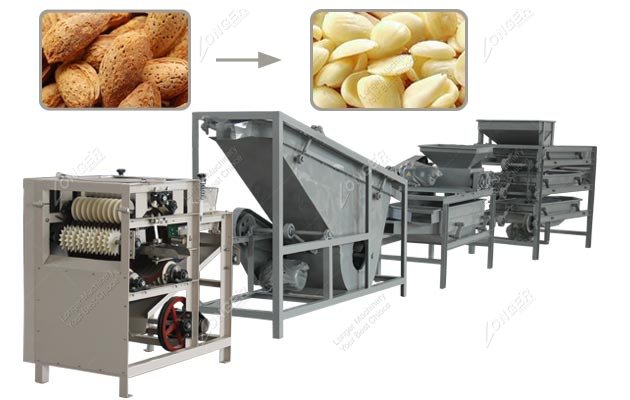

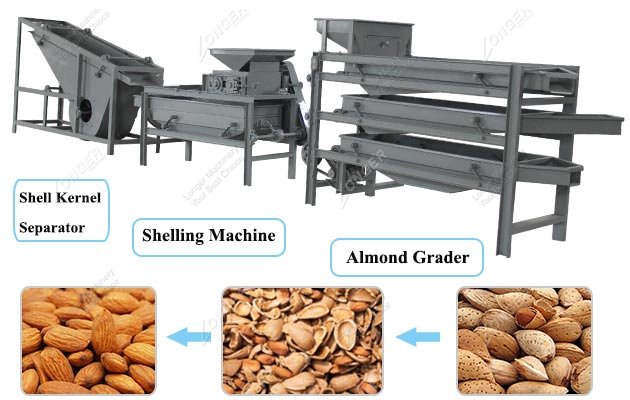

This equipment consists of lifting, grading machine, shelling machine, shell separator, almond peeling machine(customers are free to choose).

1. Raw almonds by the hopper into the grading machine (graded according to the size of raw materials is divided into several levels, followed by the assembly of several shelling machine and separator machine) is divided into three levels of size, then divided respectively into three shelling machine by hopper.

2. Almond shelling equipment (shelling gap can be adjusted according to the size of the corresponding raw materials to achieve the shell clean, nuts integrity) shell and kernel respectively into the three shell split separator.

3. The separator divides the nut shells and the kernels. One of its mouth is out of the kernel and the other is out of the shells.

Advantages of Almond Processing Equipment:

According to the size of the production and the size of raw materials, the almond shelling line can be designed and customized.

If you have any questions or need a machine quote, please contact: Email:serena@machinehall.com Whatsapp/Mobile: +8615515597212

Working Principle of Almond Processing Line:

This equipment consists of lifting, grading machine, shelling machine, shell separator, almond peeling machine(customers are free to choose).

1. Raw almonds by the hopper into the grading machine (graded according to the size of raw materials is divided into several levels, followed by the assembly of several shelling machine and separator machine) is divided into three levels of size, then divided respectively into three shelling machine by hopper.

2. Almond shelling equipment (shelling gap can be adjusted according to the size of the corresponding raw materials to achieve the shell clean, nuts integrity) shell and kernel respectively into the three shell split separator.

3. The separator divides the nut shells and the kernels. One of its mouth is out of the kernel and the other is out of the shells.

Advantages of Almond Processing Equipment:

- Capacity 300-500 kg/h, suitable for small or midium scale processing plant or almond processing business operators.

- Wide application: it can process different kinds of nuts, like hazelnut, almond, palm kernels, etc.

- The shelling rate is higher than 96% and lose rate is less than 0.5%.

- Efficient production, saving manpower and time.

According to the size of the production and the size of raw materials, the almond shelling line can be designed and customized.

If you have any questions or need a machine quote, please contact: Email:serena@machinehall.com Whatsapp/Mobile: +8615515597212

Technical Data

| Hoist |

Dimension: 600*600*6500mm Power: 0.75kw/ 380v-50hz |

| Grading Screening Machine |

Three level Dimension: 3500*1100*2000 mm Material: Carbon steel Power: 1.5kw/380v/50hz |

| Dividing Hopper | Dimension: 2000*700*1300 mm |

| Shelling Machine |

Dimension: 3500*900*1300 mm Power: 3kw/380v/50hz |

| Shell Separator Machine |

Dimension: 3200*900*1600 mm Power: 3kw/380v/50hz |

| Picking Belt |

Dimension: 6000*900*800 mm Power: 1.1kw/380v/50hz |

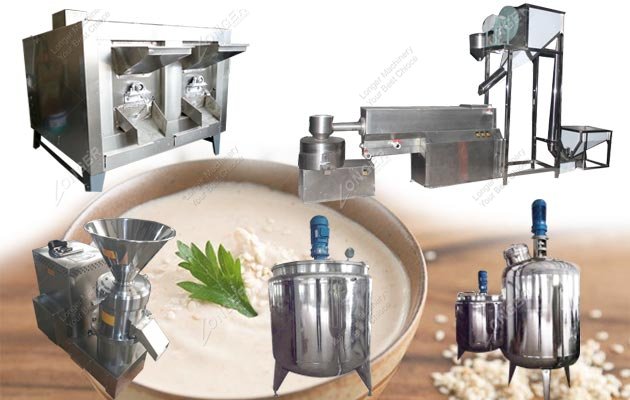

Related Products