What Is The Difference Between Batch Fryer And Continuous Fryer?

May21, 2024

May21, 2024

By Serena

By Serena

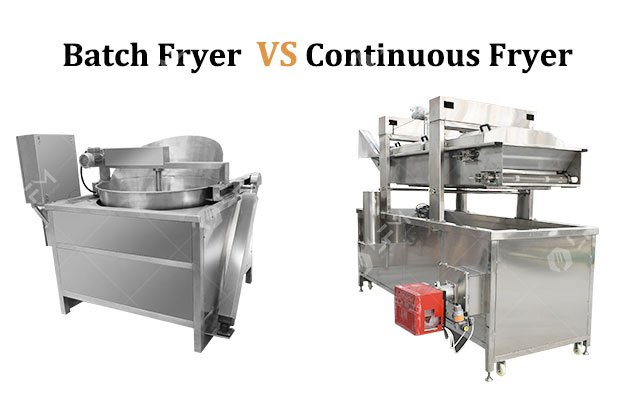

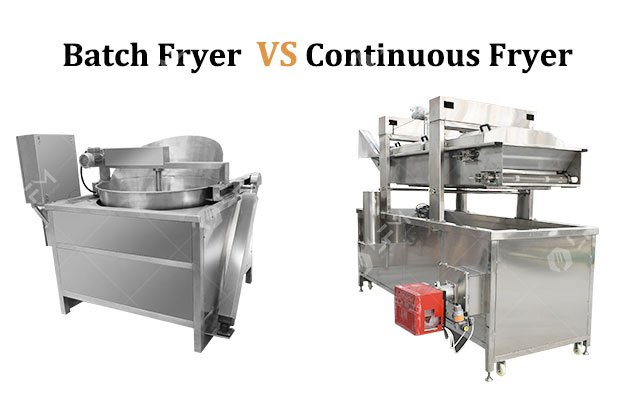

As a widely used food processing technology, frying plays an important role in improving the taste of food and extending its shelf life. With the development of technology, frying equipment has also continued to evolve. Among them, batch fryers and continuous fryers are the two main types, meeting the needs of enterprises of different sizes and types. So what is the difference between batch fryer and continuous fryer?

Batch Fryer Overview:

Batch Fryer Overview:

Batch fryer, as the name suggests, refers to processing a certain amount of raw materials at one time, completing one frying cycle before proceeding to the next batch. Batch-type fryers are usually suitable for small-scale production or places with high requirements for individualized product processing. Its main features include:

1. High flexibility: batch fryer can be adjusted according to the characteristics of different products frying time and temperature, adaptability, suitable for multi-species, small batch production.

1. High flexibility: batch fryer can be adjusted according to the characteristics of different products frying time and temperature, adaptability, suitable for multi-species, small batch production.

2. Precise control: due to the relatively small amount of frying each time, the operator can more finely control the oil temperature and time to ensure the consistency of product quality in each batch.

3. Relatively low maintenance costs: Compared with continuous fryers, batch-type equipment is simpler in structure, with lower initial investment and routine maintenance costs.

However, batch fryers also have limitations such as relatively low efficiency, poor energy utilization, and difficulty in realizing large-scale continuous production.

Continuous Fryer Overview

However, batch fryers also have limitations such as relatively low efficiency, poor energy utilization, and difficulty in realizing large-scale continuous production.

Continuous Fryer Overview

The continuous frying machine is specially designed for large-scale industrial production. It can continuously feed, fry and discharge materials, which greatly improves production efficiency. Its main features are as follows:

1. Efficient automation: The continuous fryer realizes continuous feeding and discharging of raw materials through a mesh belt transmission system. It has a high degree of automation and reduces labor, thereby improving production efficiency.

2. Oil optimization: Equipped with automatic filtering and slag discharge systems, it can effectively extend the service life of frying oil, keep the oil fresh, reduce fuel consumption, and ensure the stable quality of fried products.

3. Precise temperature control: Advanced temperature control technology is used to ensure that the oil temperature remains constant throughout the frying process. Suitable for products with strict requirements on frying conditions.

4. Large-scale production: It is suitable for enterprises that require large-scale and rapid production, such as the manufacturing of potato chips, chicken nuggets, etc. The continuous fryers can significantly increase production capacity.

Although continuous fryers have advantages in efficiency and output, their high initial investment, complex maintenance needs, and large production space requirements are also factors that companies need to consider when choosing.

In Conclusion:

Although continuous fryers have advantages in efficiency and output, their high initial investment, complex maintenance needs, and large production space requirements are also factors that companies need to consider when choosing.

In Conclusion:

In summary, batch fryers and continuous fryers each have their own advantages and disadvantages, and which type to choose depends on the specific needs of the company. When choosing, companies can consider factors such as production capacity needs, automation needs, costs, and diversity of finished products.

In the rapidly developing food processing industry, understanding the differences between these two types of frying machines can help companies make more informed investment decisions and stand out in the fiercely competitive market.

In the rapidly developing food processing industry, understanding the differences between these two types of frying machines can help companies make more informed investment decisions and stand out in the fiercely competitive market.

Contact Us:

Email: serena@machinehall.com

WhatsApp/Mobile: +8615515597212

Prev:

Prev: