Industrial Peanut Butter Processing Equipment 300 kg/h

- Material: Peanut seeds

- Capacity: 300 kg/h

- Loading Port:Qingdao Port

- Warranty:12 Months

- Quote Form:FOB, CIF, EXW, CFR

Features

The peanut butter processing equipment can realize the production from peanut seeds to peanut butter, including roasting, peeling, grinding and filling. Professional industrial peanut butter machine with high degree of automation, stable performance, safety and sanitation.

Peanut Butter Production Line General Equipment:

roasting machine, cooling belt, peeling machine, sorting belt, coarse grinding machine, superfine grinding machine, butter cooling machine, storage tank, degassing tank, filling machine.

The whole set of equipment supports customization and can be adjusted according to the user's peanut butter processing technology.

roasting machine, cooling belt, peeling machine, sorting belt, coarse grinding machine, superfine grinding machine, butter cooling machine, storage tank, degassing tank, filling machine.

The whole set of equipment supports customization and can be adjusted according to the user's peanut butter processing technology.

(1) Peanut roasting machine: roast the peanuts. The hot air penetrates the material evenly to ensure the maturity of the roasting, thereby improving the quality of peanut butter.

(2) Cooling belt: the principle of using the fan to remove the heat to cool the roasted peanuts.

(3) Peanut peeling machine: to remove the skin of the roasted peanuts. In the process of peeling, skin and kernel automatic separation to ensure the quality of peanut after peeling.

(4) Screening belt: choose the unqualified peanut and some food residue.

(5) Coarse peanut grinding machine: first grinding of peanut.

(6) Secondary peanut butter grinding machine: further grinding thepeanut butter, and further improving the peanut butter fineness.

(7) Peanut butter cooling machine: using foreign technology, improved and reached the advanced level at home and abroad, is the ideal equipment for peanut butter cooling, with fast cooling, easy cleaning and so on.

(8) Storage tank: Temporarily store ground peanut butter.

(9) Mixing tank: seasoning peanut butter, you can make peanut butter with different flavors.

(10) Degassing tank: degassing peanut butter before filling.

(9) Mixing tank: seasoning peanut butter, you can make peanut butter with different flavors.

(10) Degassing tank: degassing peanut butter before filling.

(11) Peanut butter filling machine: Complete the whole process of filling, capping and labeling.

Application of Peanut Butter Processing Equipment:

This processing line can produce smooth peanut butter, crunchy peanut butter, granular peanut butter, etc. With large output and high efficiency, it is the best choice for small and medium-sized peanut butter processing plant.

In addition, you can also make nut butters such as almond butter, cashew butter, and sesame butter by making slight adjustments to this set of peanut butter machine.

This processing line can produce smooth peanut butter, crunchy peanut butter, granular peanut butter, etc. With large output and high efficiency, it is the best choice for small and medium-sized peanut butter processing plant.

In addition, you can also make nut butters such as almond butter, cashew butter, and sesame butter by making slight adjustments to this set of peanut butter machine.

Advantages of Industrial Peanut Butter Processing Machine:

- Fully automatic and continuous production. Very efficient.

- Centralized control, reducing labor costs, and simple operation.

- The closed unmanned operation ensures that the product quality meets the food hygiene production standards.

- Customization: We can design a complete set of peanut butter line according to the drawings of the user's factory.

Technical Data

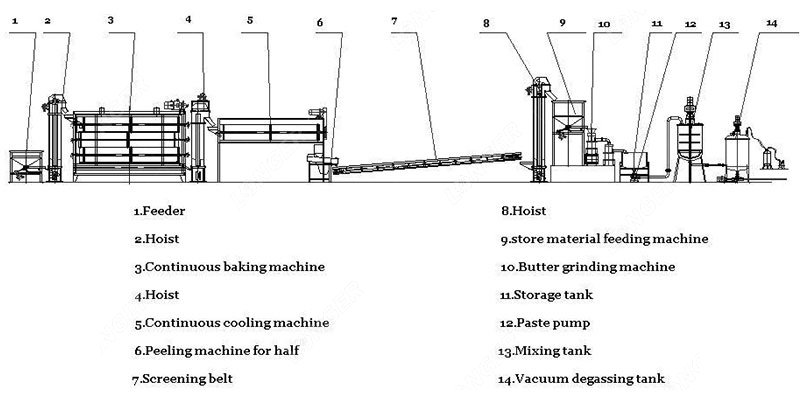

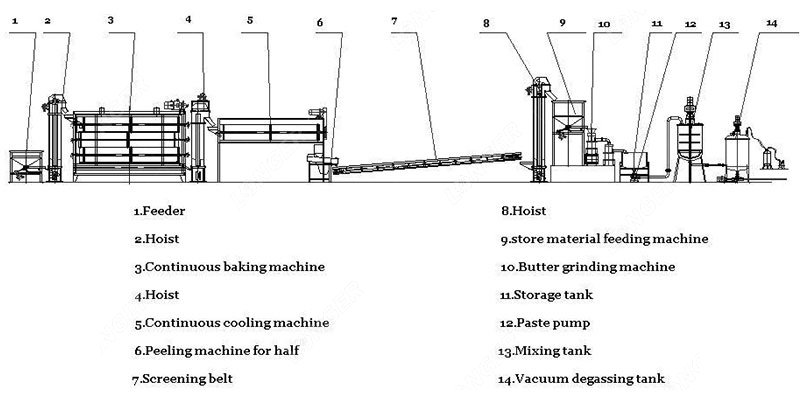

| No. | Name | Power(KW) | Size(mm) |

| 1 | Feeder | 0.55 | 700*700*800 |

| 2 | Hoist | 0.75 | 1000*500*2800 |

| 3 | Continuous baking machine | 70 | 5.8*1200*2600 |

| 4 | Hoist | 0.75 | 1000*500*3000 |

| 5 | Continuous cooling machine | 8 | 6000*800*2600 |

| 6 | Peeling machine for half | 1.5 | 1100*700*1300 |

| 7 | Screening belt | 0.75 | 5000*800*1000 |

| 8 | Hoist | 0.75 | 1000*500*3400 |

| 9 | store material feeding machine | 0.55 | 700*700*2200 |

| 10 | Butter grinding machine | 11*2 sets | 1000*350*900 |

| 11 | Storage tank | 200L | |

| 12 | Paste pump | 1.5 | 1200*300*350 |

| 13 | Mixing tank | 2.2 | 300L |

| 14 | Vacuum degassing tank | 2.2 | 300L |

| 15 | Paste pump | 1.5 | 1200*300*350 |

| 16 | Control cabinet | ||

| 17 | Pipeline |

Related Products