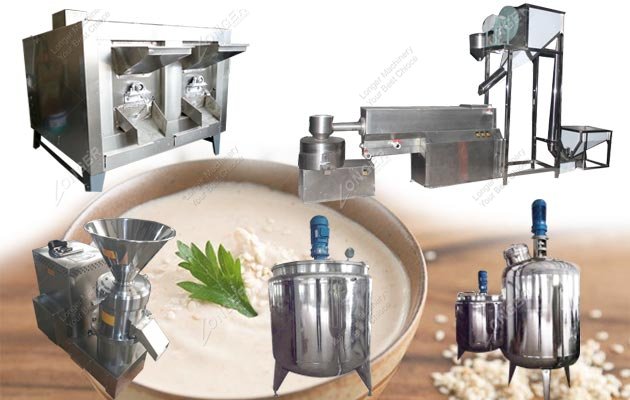

Automatic Groundnut Butter Paste Production Line 200 kg/h

- Material: Groundnut Butter,Groundnut Paste

- Capacity: 200kg/h

- Loading Port:Qingdao Port

- Warranty:12 Months

- Quote Form:FOB, CIF, EXW, CFR

Features

The groundnut butter production line can complete the production from raw groundnut roasting to finished groundnut paste filling, and can be used to manufacture smooth peanut butter, crunchy peanut butter, salted peanut butter, etc.

The whole line is made of food-grade stainless steel, which has the advantages of high automation, easy-operating integrated control, stable performance, high product quality, etc.

Groundnut Butter Processing Flow:

Groundnuts--Roasting--Conveying--Cooling--Peeling--Picking-- Grinding--Storage--Mixing--Vacuum Degassing--Paste Cooling--Paste Filling

Introduction of Automatic Groundnut Paste Production Line

It consists of a roaster, conveyor, cooling machine, peeling machine, sorting belt, grinding machines, pump, storage tank, cooling machine, mixing machine, vacuum degassing tank, filling machine, etc.

1. Groundnut Roasting Machine: The machine adopts a rotary rolling cage, the groundnuts are heated evenly, and the baking quality is high. The machine is also equipped with an automatic temperature control device.

2. Cooling Belt: Use the principle of the fan to extract the hot air to cool the roasted peanuts

3. Groundnut Peeling Machine: Peel the roasted peanuts. During the peeling process, the skin and kernel are automatically separated, and the peeling effect is good.

4. Groundnut Grinding Machine: Finely ground peanuts, the groundnut butter fineness can reach 100mesh. The main parts are made of stainless steel, which is corrosion-resistant and non-toxic.

5. Storage Tank: It settles in the storage tank until the temperature of the groundnut butter drops to the air temperature.

6. Mixing Tank: Stir to make the groundnut paste more even.

7. Vacuum Degassing Tank: Degas the groundnut butter before filling.

8. Groundnut Paste Cooling Machine: Cooling water is used to quickly cool the groundnut paste, so as to meet the requirements of the next process.

9. Groundnut Butter Filling Machine: Fill the finished groundnut butter into bottles or bags. The filling volume is controlled according to time, and the filling volume is accurate,

Advantages of the Groundnut Butter Production Line

1. The closed and unmanned production environment ensures that the product quality meets the food hygiene production standards.

2. High degree of mechanization and centralized control. While reducing labor costs, it can also greatly improve production efficiency.

3. A variety of production capacities are available to meet the needs of production enterprises of different scales. Available capacities are 200 kg/h, 500 kg/h, 1 t/h, etc.

4. The whole line has complete functions, stable operation, easy maintenance and cleaning.

5. The whole line supports customization, provides factory drawings and complete installation and after-sales service.

Types of Groundnut Butter:

1. The closed and unmanned production environment ensures that the product quality meets the food hygiene production standards.

2. High degree of mechanization and centralized control. While reducing labor costs, it can also greatly improve production efficiency.

3. A variety of production capacities are available to meet the needs of production enterprises of different scales. Available capacities are 200 kg/h, 500 kg/h, 1 t/h, etc.

4. The whole line has complete functions, stable operation, easy maintenance and cleaning.

5. The whole line supports customization, provides factory drawings and complete installation and after-sales service.

Types of Groundnut Butter:

According to different tastes, groundnut butter is divided into sweet and salty. It is a nutritious seasoning food and is widely used in Western food. Generally divided into two types: smooth and crunchy. Crunchy peanut butter is to add peanut particles to the finished groundnut butter to increase its taste.

Groundnut paste is often used as noodles, steamed bread, bread or salad dressing.

Technical Data

| No. | Name | Power(kw) | Size(mm) | Qty |

| 1 | Roaster | 47.2 | 2900*2100*1700 | 1 |

| 2 | Convey Belt | 0.75 | 3600*700*1500 | 1 |

| 3 | Cooling Belt | 6 | 6000*1200*1600 | 1 |

| 4 | Peeling Machine | 0.74 | 1100*450*1100 | 1 |

| 5 | Picking Belt | 0.75 | 6000*800*1000 | 1 |

| 6 | Elevator | 0.75 | 1000*500*4200 | 1 |

| 7 | Storage Tank | 1200*1200*3800 | 1 | |

| 8 | Peanut Butter Grinder | 11*3 | 1250*550*1100 | 1 |

| 9 | Chiller | 3P | 1200*600*1200 | 1 |

| 10 | Storing Tank | 1000*1000*900 | 1 | |

| 11 | Mixing Tank | 2.2 | 300L | 1 |

| 12 | Vacuum Degassing Tank | 2.2+1.5 | 300L | 1 |

| 13 | Paste Cooling Machine | 0.75 | 2000*400*1700 | 1 |

| 14 | Filling Machine | |||

| 15 | Workbench | 1200*1200*800 | 1 | |

| 16 | Paste Pump | 1.5*3 | 1200*300*350 | 3 |

Related Products