LG-YMTF1000 Oat Shelling and Separating Machine Fully Automatic

- Material: Oats

- Capacity: 1000 kg/h

- Loading Port:Qingdao Port

- Warranty:12 Months

- Quote Form:FOB, CIF, EXW, CFR

Features

This set of oat shelling machine can realize hulling, separating, sorting, and re-selection processes, and the whole kernel rate can reach more than 95%. This equipment has the characteristics of high degree of automation, low labor intensity, low energy consumption, compact structure and small space, etc.

More details, please contact:

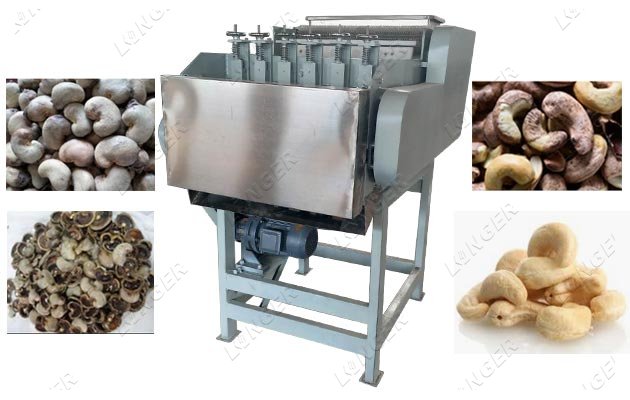

Main components of an oat shelling and seprating machine:

Loading hopper, raw material lifter, sheller, skin and seed separating screen, seed and kernel sorting screen, cyclone separator, unloader, re-selecting machine, centralized control cabinet.

- After shelling, the material is a mixture of skin, seeds, and kernels, which enters into a seed and kernel sorting machine to remove the skin from the mixture.

- The unhulled seeds will enter the inlet of the air suction and return system backward, and will be lifted into the sheller and then shelled again.

Advantages of Fully Automatic Oat Shelling Machine

- High shelling rate and whole kernel rate: after shelling, the kernel contain in skin is less than 5% kernels, and the whole kernel rate can reach over 95%.

- Cleaned materials after shelling: there is a device for removing impurities before shelling, which makes the hulled material more clean.

- The wide screen surface design improves the sorting efficiency.

- High production efficiency: fully automated production, the output of this set of equipment can reach 1000 kg per hour.

- Save labor: The equipment adopts unit control, and the whole unit operation only needs two people to operate.

More details, please contact:

Email: serena@machinehall.com

Whatsapp/Mobile: +8615515597212

Technical Data

| Model | LG-YMTF1000 |

| Capacity | 1000 kg/h |

| Power | 12.25kw |

| Space | 7.3*2.8m |

| Weight | 2.8T |

| Whole kernel rate | over 95% |

| Percentage of seeds in kernels | less than 2% |

Related Products