Small Hazelnut Almond Cracking Drying Equipment Manufacturer

- Material: hazelnut,almond,chestnut

- Capacity: 300-500kg/h

- Loading Port:Qingdao Port

- Warranty:12 Months

- Quote Form:FOB, CIF, EXW, CFR

Features

Introduction of Small Hazelnut Cracking Drying Equipment

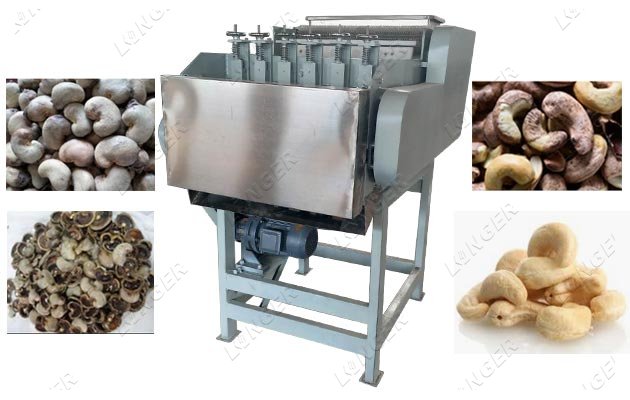

This machine includes hoister, nut grading machine, hazelnut/almond cracking machine, shell and kernel separator, nut kernel roasting machine and hazelnut peeling machine.

The small almond cracking drying machine with capacity of 300-500kg/h is capable of effectively cracking hazelnut and almond with varying nut sizes, making it ideal for small or medium sized hazelnut and almond processing plant. It has the advantages of low energy consumption, high cracking rate and peeling rate.

An introduction to the main components of almond cracking drying equipment:

1. Almond screening machine:

It is mainly used to filter different sizes of apricot kernels, hazelnuts, almonds and other nuts into multiple sizes, which is conducive to shelling process.

2. The single-stage hazelnut cracking equipment:

It is a device for shelling hazelnuts, apricot kernels, and peach kernels. Single-stage shattered shell, relative clearance can be adjusted, reliable principle, strong and durable. The device is mainly through the relative extrusion of two rollers, squeezing the nut shell to achieve the shelling of the nuts. After the hazelnut is poured into the machine and broken once, there is a portion of the unbroken hazelnuts that need to be screened, and the gap between the two sticks is adjusted again to break the shell.

3. Almond shell and kernel separator:

The machine is composed of hopper, sieve body, fan and frame, eccentric drive mechanism and so on. Rubber bearing is adopted at the junction of the reciprocating movement, and the rubber bearing has the characteristics of durability, shock absorption and so on. This machine can achieve better separation effect by adjusting the size of the inlet and the angle of the vibrating screen.

4. Almond hazelnut drying machine:

It is composed by feeding device, speed regulating motor, drive mechanism, circulating fan, electric cabinet and other parts. Control blowing rate and set the temperature of the material being heated by regulating running speed to ensure best roasting effect. Widely used in food, electronics, chemical industry, etc. Such as peanuts, cashews, walnuts, pistachio, almond, broad bean and other granular nuts, materials.

Hazelnut Cracking Drying Machine Plant Video:

As the professional almond cracking drying equipment manufacturer, we have strong R & D strength and strict management system, and our company is unique in the domestic nut shelling machinery market.

Persistent quality standards and strong r&d investment have made the machines of the brand more popular and far ahead of other competitors.

This machine includes hoister, nut grading machine, hazelnut/almond cracking machine, shell and kernel separator, nut kernel roasting machine and hazelnut peeling machine.

The small almond cracking drying machine with capacity of 300-500kg/h is capable of effectively cracking hazelnut and almond with varying nut sizes, making it ideal for small or medium sized hazelnut and almond processing plant. It has the advantages of low energy consumption, high cracking rate and peeling rate.

An introduction to the main components of almond cracking drying equipment:

1. Almond screening machine:

It is mainly used to filter different sizes of apricot kernels, hazelnuts, almonds and other nuts into multiple sizes, which is conducive to shelling process.

2. The single-stage hazelnut cracking equipment:

It is a device for shelling hazelnuts, apricot kernels, and peach kernels. Single-stage shattered shell, relative clearance can be adjusted, reliable principle, strong and durable. The device is mainly through the relative extrusion of two rollers, squeezing the nut shell to achieve the shelling of the nuts. After the hazelnut is poured into the machine and broken once, there is a portion of the unbroken hazelnuts that need to be screened, and the gap between the two sticks is adjusted again to break the shell.

3. Almond shell and kernel separator:

The machine is composed of hopper, sieve body, fan and frame, eccentric drive mechanism and so on. Rubber bearing is adopted at the junction of the reciprocating movement, and the rubber bearing has the characteristics of durability, shock absorption and so on. This machine can achieve better separation effect by adjusting the size of the inlet and the angle of the vibrating screen.

4. Almond hazelnut drying machine:

It is composed by feeding device, speed regulating motor, drive mechanism, circulating fan, electric cabinet and other parts. Control blowing rate and set the temperature of the material being heated by regulating running speed to ensure best roasting effect. Widely used in food, electronics, chemical industry, etc. Such as peanuts, cashews, walnuts, pistachio, almond, broad bean and other granular nuts, materials.

Hazelnut Cracking Drying Machine Plant Video:

As the professional almond cracking drying equipment manufacturer, we have strong R & D strength and strict management system, and our company is unique in the domestic nut shelling machinery market.

Persistent quality standards and strong r&d investment have made the machines of the brand more popular and far ahead of other competitors.

Technical Data

| Machine | Parameter |

| Hazelnut Elevator Machine |

Capacity: 500kg/h Power: 0.75kw Voltage: 380V Dimension: 2500*600*2000mm |

| Hazelnut Cracking Equipment |

Capacity: 400-500kg/h Power: 2.2kw Voltage: 380V Dimension: 1900*780*1200mm Weight: 280kg |

| Hazelnut Separating Machine |

Capacity: 500-800kg/h Power: 3kw Voltage: 380V Dimension: 2300*800*1600mm Weight: 200kg |

| Hazelnut Grading Machine |

Dimension: 1.9*0.8*1.4m Power: 1.1kw Voltage: 380v,50hz Capacity: 500kg/h Weight: 140kg |

| Hazelnut Drying Equipment LG-6 |

Layers: 3 Motor power: 1.5kw Roasting power: 70-90kw Gas: 15-20kg/h Dimension: 6*1.6*2.5m |

| Hazelnut Peeling Machine |

Dimension: 1.5*0.5*1M Power: 0.2kw Voltage: 220v,50hz Capacity: 400-500kg/h Weight: 380kg |

Related Products