400 KG/H Buckwheat Shelling Dehulling Machine Production Line

- Material: Buckwheat

- Capacity: 400 KG/H

- Loading Port:Qingdao Port

- Warranty:12 Months

- Quote Form:FOB, CIF, EXW, CFR

Features

The buckwheat shelling production line adopts the way of grading first and then shelling, so the shelling separation effect is good, the efficiency is high, the whole rice rate is high, and the integrity of buckwheat shell is guaranteed to the greatest extent. It is the best buckwheat dehulling equipment in the world with high automation.

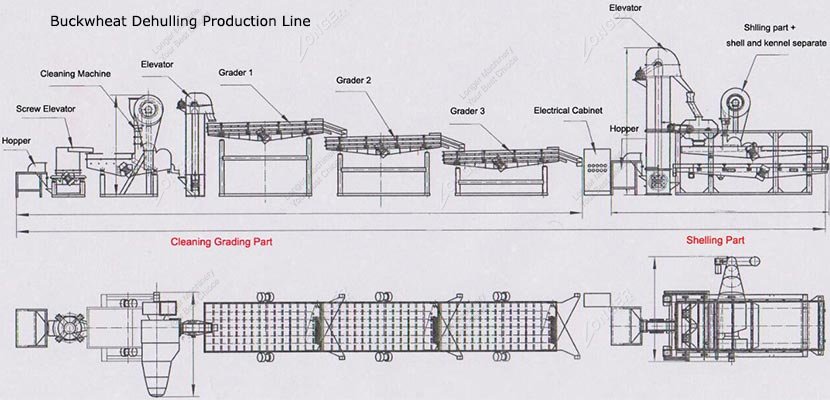

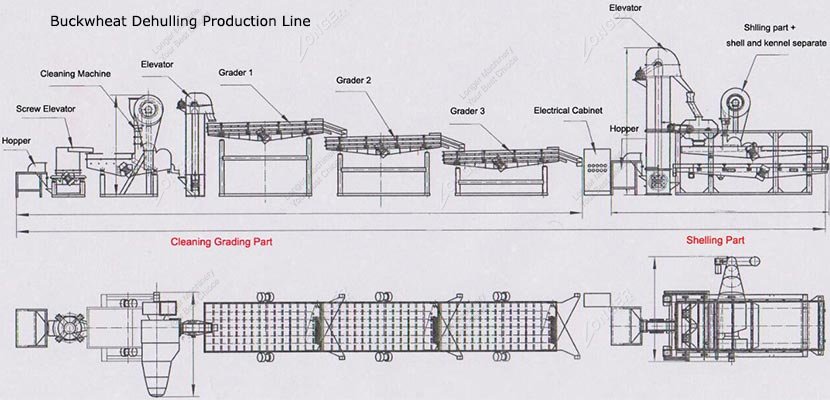

Component of Buckwheat Dehulling Production Line

Process Flow:Raw material cleaning, impurity removal → classification (6-7 levels) → shelling (single level) → peeling → sorting → buckwheat rice

The unshelled seeds are returned to the sheller for further shelling and continuous operation. Buckwheat, broken buckwheat and buckwheat shells are excluded from the export.

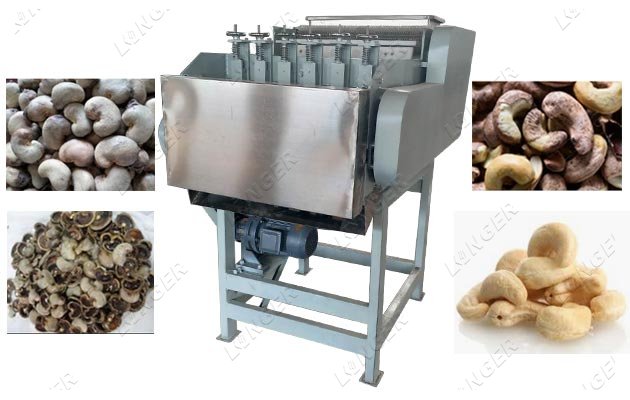

Usage of 400 KG/H Buckwheat Dehulling Machine:

Nuts like Pine nut, buckwheat, inchi nut, moringa seed, sunflower seed, safflower seed, hemp seeds, pumpkin seed, melon seed, egusi etc.

Structure Advntages of Buckwheat Shelling Machine

Component of Buckwheat Dehulling Production Line

- Cleaning and grading unit: on the hopper, raw material hoist, multi-function machine, bucket elevator, grading machine and electronic control cabinet.

- Shelling and seperating unit: on the hopper, hoist, shelling sorting host, the additional sieve section and control cabinet.

Process Flow:Raw material cleaning, impurity removal → classification (6-7 levels) → shelling (single level) → peeling → sorting → buckwheat rice

The unshelled seeds are returned to the sheller for further shelling and continuous operation. Buckwheat, broken buckwheat and buckwheat shells are excluded from the export.

Usage of 400 KG/H Buckwheat Dehulling Machine:

Nuts like Pine nut, buckwheat, inchi nut, moringa seed, sunflower seed, safflower seed, hemp seeds, pumpkin seed, melon seed, egusi etc.

Structure Advntages of Buckwheat Shelling Machine

- The multifunctional cleaning machine can remove large impurities, small impurities, stones, glass, withered seeds, hair and other debris with similar size and weight properties.

- The pneumatic device of material backflow can automatically backflow the seeds not shelled to the sheller to improve the shelling rate.

- The main parts of the sheller are all steel, and the impeller is made of 99% alumina ceramic, which improves the shelling effect and prolongs the service life.

- Porous sieve plate, through the stamping work of high-quality cold-rolled sheet, is durable, making the separation of grains easier.

- All electrical works of the equipment are centrally controlled by the electrical control cabinet, and the operation interface is simple.

Technical Data

| Processing technician | Machine | Quantity | Capacity |

| Dehuller Unit | Input Hopper | 2 | 400KG/H |

| Elevator | 2 | ||

| Dehuller | 2 | ||

| Sorting sieve section | 4 | ||

| Control cabinet | 1 | ||

| Cleaning&Grading | Input Hopper | 1 | 800-1000kg/H |

| Elevator | 1 | ||

| Multifunctional impurity remover | 1 | ||

| Bucket elevator | 1 | ||

| Classification unit | 3 | ||

| Control cabinet | 1 |

Related Products