Continuous Walnut Hazelnut Butter Production Line Solution

- Material: Hazelnut, Walnut

- Capacity: 100-200 kg/h

- Loading Port:Qingdao Port

- Warranty:12 Months

- Quote Form:FOB, CIF, EXW, CFR

Features

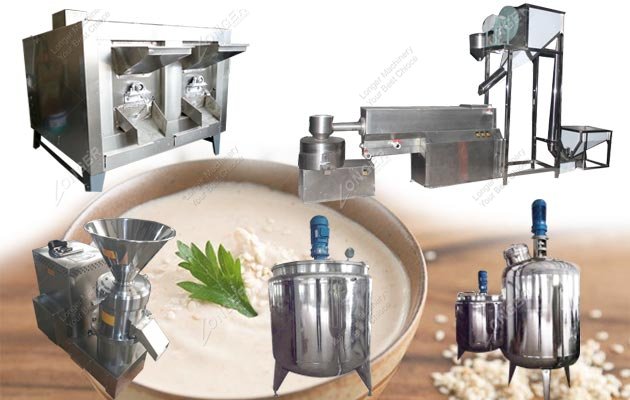

This walnut butter production line is a continuous automated equipment for the production of smooth and crunchy nut butters. This set of equipment can complete the whole process from raw material roasting to finished sauce filling. Fully enclosed production, no pollution, stable operation.

After some adjustments, this hazelnut butter production line can also be used to produce high-quality peanut butter, almond butter, walnut paste, cashew butter and other nut butters. Provide consumers with healthy, different flavored nut butter products.

After some adjustments, this hazelnut butter production line can also be used to produce high-quality peanut butter, almond butter, walnut paste, cashew butter and other nut butters. Provide consumers with healthy, different flavored nut butter products.

Process flow of hazelnut butter production line:

Walnut/Hazelnut -- Roasting -- Conveying -- Cooling --Grinding -- Storage -- Cooling -- Mixing -- Vacuum degassing -- Filling -- Capping -- Sealing

Introduction of Walnut Butter Production Line

The core general equipment includes: roasting machine, cooling belt, picking belt, walnut butter grinder, mixing tank, transfer pump, vacuum tank, degassing tank, cooler, filling machine, etc.

1. Walnut Hazelnut Roasting Machine

This is a mesh belt roasting machine, which consists of a frame, a conveyor mesh belt, a heating device and a thermal cycle device.

The heating device and the thermal circulation device make the even circulating hot air generated in the oven. The hot air penetrates the material upward from the lower part of the mesh belt and then passes through the heating element to supplement the heat energy. Automatic temperature control.

This is a colloid mill, which can subject the material to physical effects such as strong shear, friction, high-frequency vibration, high-speed vortex, etc., to achieve the effect of ultra-fine crushing and emulsification of the material. Made of stainless steel, corrosion-resistant and non-toxic. This grinding machine can produce hazelnut paste, almond butter, cashew butter, etc.

3. Nut Butter Cooling Machine

During the movement of the walnut sauce, the cooling water between the cooling outer tube and the inner tube continuously absorbs the heat in the walnut sauce until the temperature of the walnut sauce and the temperature of the cooling water reach equilibrium.

4. Vacuum Degassing Tank

By vacuum degassing the sauce, it can inhibit browning, oxidation of pigments, vitamins, aroma components and other substances, and prevent quality degradation. It can be used in conjunction with the sterilization unit.

5. Walnut Butter Filling Machine:

Fill the finished walnut butter into a 200g/500g/1000g bottle. The filling volume can be adjusted to achieve precise filling results. The filling machine is suitable for filling liquid and cream products with different viscosities.

Application of Hazelnut Butter Production Line

The production line can produce original hazelnut paste, seasoned hazelnut paste, and crunchy hazelnut paste. It is also suitable for other nut butters, such as peanut butter, almond butter, cashew nut butter, walnut butter, pistachio butter, macadamia nut butter, etc.

If you are interested in this equipment, welcome to contact us. We will customize a complete solution for you according to your specific needs.

Email: serena@machinehall.com

WhatsApp/Mobile: +8615515597212

Technical Data

| No. | Name | Power(kw) | Size(mm) |

| 1 | Feeder | 0.55 | 700*700*800 |

| 2 | Hoist | 0.75 | 1000*500*2800 |

| 3 | Continuous roasting machine | 70 | 6000*1500*1450 |

| 4 | Continuous cooling machine | 8 | 6000*800*2600 |

| 5 | Peeling machine for half | 1.5 | 1100*700*1300 |

| 6 | Screening belt | 0.75 | 5000*800*1000 |

| 7 | Butter grinding machine | 11*2 sets | 1000*350*900 |

| 8 | Storage tank | 200L | |

| 9 | Paste pump | 1.5 | 1200*300*350 |

| 10 | Mixing tank | 2.2 | 300L |

| 11 | Vacuum degassing tank | 2.2 | 300L |

Related Products