Complete Walnut Almond Milk Production Line Equipment 100KG

- Material: Almond, Walnut

- Capacity: 100-200 kg/h

- Loading Port:Qingdao Port

- Warranty:12 Months

- Quote Form:FOB, CIF, EXW, CFR

Features

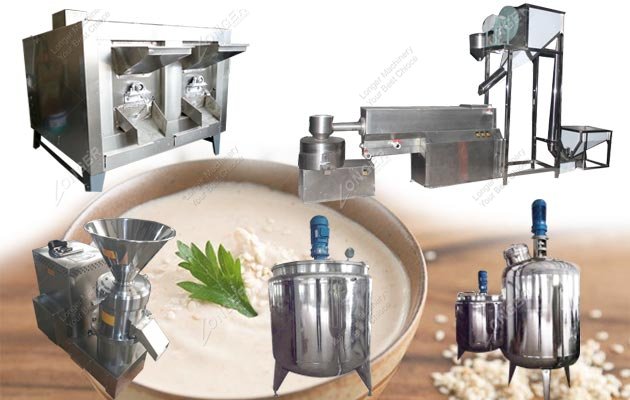

This set of walnut almond milk production line can complete the processes of peeling, grinding, filtering, mixing, homogenizing, sterilizing, and filling. Advanced technology and complete functions ensure the quality of nut milk.

The almond milk production equipment can also produce walnut milk, peanut milk, soy milk, tiger nut milk, etc., with a wide range of uses.

Almond Milk Processing Flow:

Peeling -- Grinding -- Filter -- Storage Tank -- Mixer -- Homogeneous -- Boiling -- Storage Tank -- Filling

Introduction of Complete Almond Milk Production Line

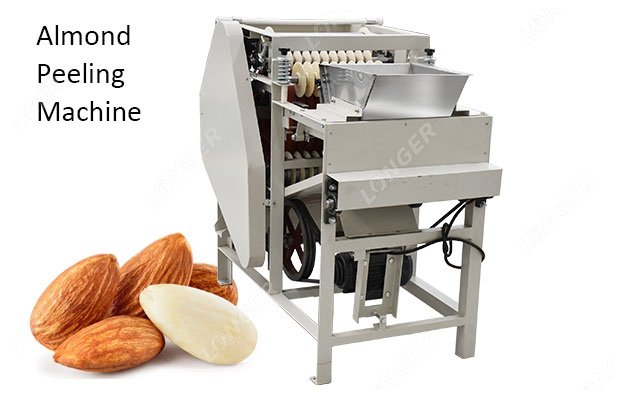

1. Almond Peeling Machine: To remove the almond skin.

The machine adopts the principle of imitating the peeling by hand and the special peeling principle. While peeling, the skin and kernels are automatically separated. After undressing, the almonds are not broken, the color is bright, the surface is not browned, and the protein does not change.

2. Almond Milk Grinding Machine: To grinding almond and water into almond milk.

The colloid mill is a machine that finely grinds fluid materials and can be used to produce peanut butter, peanut milk, walnut butter, walnut milk, jam and so on. The main parts are made of stainless steel, which is corrosion-resistant and non-toxic.

3. Filter: To filter the gross from the almond milk.

The high-precision fine powder screening machine has low noise and high efficiency. It takes 3-5 minutes to quickly change the screen. It has a fully enclosed structure and is suitable for screening and filtering particles, powder, mucus and other materials.

4. Storage Tank: To filter the gross from the almond milk.

5. Mixing: At this step, you add some other material into the tank, mixing with the almond milk.

6. Homogenization: Process the originally rough emulsion or suspension into a fine, uniform liquid and liquid mixed emulsion or liquid and solid dispersion.

7. Filling: To filling the almond milk into bottle.

Advantages of Complete Walnut Milk Production Line

- The complete set of walnut milk processing equipment realizes the whole process and has a high degree of mechanization.

- The core equipment of the nut milk grinding machine has undergone many improvements and optimizations, and the processing fineness has been further improved.

- Fully enclosed production meets the conditions of food hygiene production and guarantees product quality.

- Simple operation, stable operation, low noise and easy maintenance.

- It has a wide range of applications, including peanut milk, almond milk, tiger nut milk, soy milk, etc.

Technical Data

| No. | Name | Power(kw) | Size (mm) |

| 1 | Almond Peeling Machine | 0.75 | 1180*720*1100 |

| 2 | Almond Milk Machine | 4 | 640*410*900 |

| 3 | Filter | 0.55 | 900*900*750 |

| 4 | Mixing Tank | / | 300L |

| 5 | Homogenizer | 11 | 1100*840 *1100 |

| 6 | Storage Tank | / | 300L |

| 7 | Filling Machine | 0.5 | / |

Related Products