Nutrition RUTF Peanut Paste Production Line with UNICEF

- Material: peanuts,nutrients

- Capacity: 500KG/H

- Loading Port:

- Warranty:12 Months

- Quote Form:FOB, CIF, EXW, CFR

Features

The RUTF peanut paste production line meets UNICEF standards, it is produced for the industrial manufacture of RUTF Food used in the treatment of severe acute malnutrition.

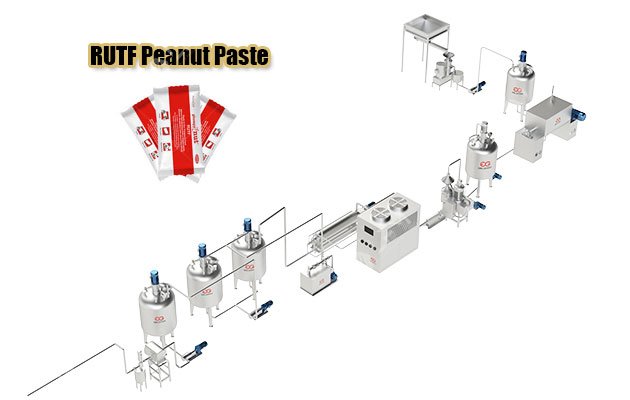

This production line integrates raw material handling, hygienic processing, precise formulation, and sophisticated packaging, enabling large-scale production of a nutritionally consistent product. It can operate continuously for extended periods, supporting humanitarian projects and government tenders.

This RUTF solution aims to transform selected peanuts and complementary ingredients into a homogeneous, shelf-stable therapeutic paste. The production process strictly adheres to international therapeutic food standards, focusing on product safety, nutrient retention, and reproducibility.

UNICEF Compliant RUTF Peanut Paste Processing Line

This solution is designed to meet international food safety standards, including GMP and HACCP, as well as UNICEF procurement guidelines. Equipment features food-grade stainless steel with smooth finishes to minimize contamination. Key processes like roasting, grinding, and mixing are precisely controlled to ensure consistent nutritional quality.

The production line enables accurate dosing of micronutrients and oils to meet standard RUTF formulations. Closed conveying, sealed mixing, and optional nitrogen protection help maintain product integrity and extend shelf life without refrigeration, aligning with distribution needs in challenging environments.

Features of RUTF Peanut Paste Production Line

- Designed for efficiency, safety, and flexibility. Its modular architecture enables tailored capacity and automation configurations.

- Nutritional RUTF peanut paste products are produced stably. The grinding and mixing ensure even distribution of micronutrients and fats.

- This RUTF peanut paste processing line with fully enclosed processing, CIP-ready components, and easy-access structures support strict sanitation routines.

- RUTF peanut paste processing is consistent. With PLC control system ensures consistent parameters across batches and shifts, resulting in same products.

- The machine is energy-saving and efficient, and the optimized roasting and grinding processes reduce energy consumption per ton of finished peanut butter.

- The production capacity range is wide from 300kg to 2000kg. Suitable for pilot plants, regional plants and large humanitarian aid projects.

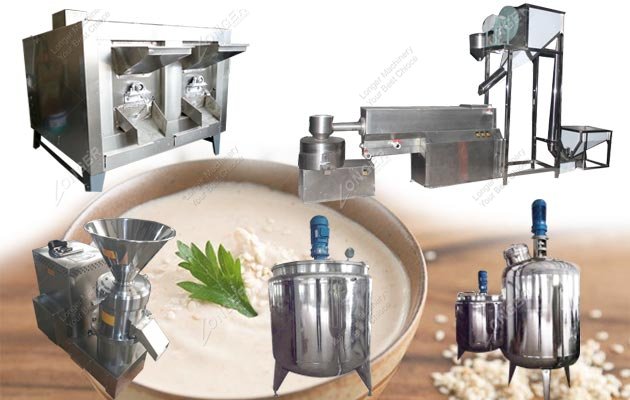

Main Equipment in RUTF Peanut Paste Production Line

- Raw Peanut Cleaning and Sorting System: Removes stones, dust, and foreign materials to ensure clean input material.

- Continuous Peanut Roaster: Provides uniform roasting to develop flavor and reduce moisture, supporting microbial safety.

- Cooling and Blanching Unit: Stabilizes roasted peanuts and facilitates skin removal where required.

- Primary and Fine Grinding Mills: Reduces peanuts into smooth paste with controlled particle size for therapeutic texture.

- High-Precision Mixing Tank: Incorporates sugar, vegetable oil, milk powder, vitamins, and minerals into a homogeneous mass.

- Buffer and Holding Tanks: Maintain steady flow to downstream packaging while protecting product quality.

- Automatic Filling and Packaging Machine: Supports sachets, cups, or jars according to distribution and program requirements.

Project Experience and Market Reference

The RUTF Peanut Paste Production Line has been delivered to customers in Nigeria and other countries for therapeutic food production. Equipment installation, commissioning, and trial operation were completed smoothly on site.

During trial runs, the line showed stable performance, uniform paste texture, and reliable ingredient mixing. Customer feedback confirms that the RUTF peanut paste solution meets practical production and quality expectations.

Technical Data

Related Products