Automatic Cashew Butter Production Line Efficient

- Material: Cashew nut

- Capacity: 100-2000kg/h

- Loading Port:Qingdao Port

- Warranty:12 Months

- Quote Form:FOB, CIF, EXW, CFR

Features

This cashew butter production line is an automated system that continuously processes raw cashews into a smooth cashew butter. It has a wide capacity range, from 100-2000 kg per hour, and is suitable for industrial processing.

Our company developed this production line with a focus on high efficiency, uniform grinding, and food safety. It can meet the diverse market demands for cashew butter quality and quantity.

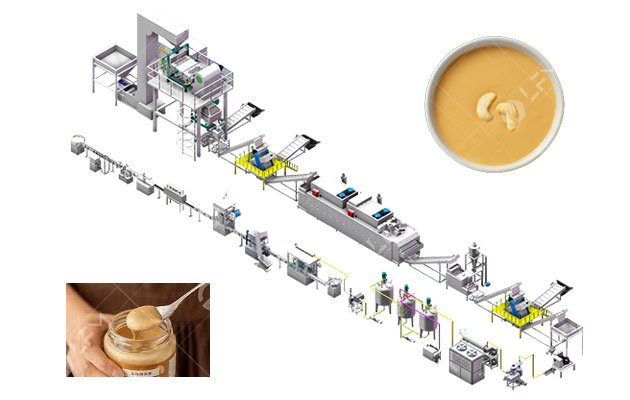

Cashew Butter Processing Line Processing Flow

Our company provides a complete processing flow, typically including raw material selection, cashew roasting, cooling and conveying, grading and grinding, homogenization and blending, and finished product filling.

After roasting, the cashews fully release their nutty aroma, and then are progressively processed into a smooth butter through a multi-stage grinding system. The entire process operates stably, contributing to improved consistency and yield of the cashew butter.

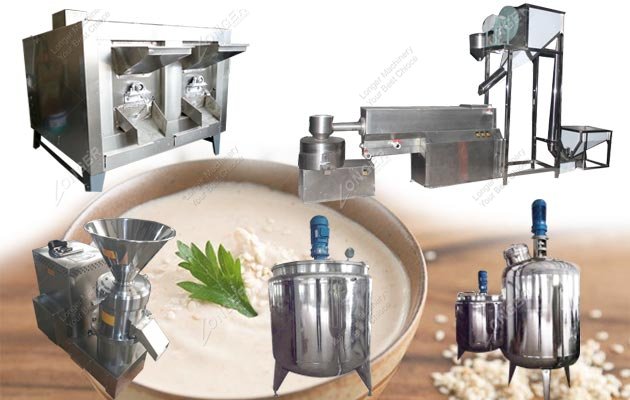

Main Equipment Components of Cashew Butter Production Line

- Grading Machine: Used to grade raw cashews by size and quality, ensuring consistency of raw materials for subsequent processing and improving overall product stability.

- Cooking Machine: Performs a pre-treatment cooking process on the cashews, making the kernel structure more stable, which is beneficial for subsequent peeling and reduces breakage.

- Cashew Roasting Machine: One of the key equipment in the cashew butter processing line, available in electric or gas heating. It roasts the cashews using uniform hot air circulation, ensuring even heating and consistent color.

- Grinding Machine: Feeds the roasted cashew kernels through the inlet and grinds them into a uniform cashew butter. The fineness of the finished product can be adjusted according to requirements.

- Mixing and Homogenizing Tank: Used for mixing, homogenizing, and adjusting the formula of the cashew butter, ensuring even oil distribution and stable taste.

- Filling Machine: Quantitatively fills the finished cashew butter, suitable for various packaging forms such as bottles and cans, meeting different market demands.

Features of the Cashew Butter Production Line

- Modular Design: Flexible equipment configuration allows for expansion based on actual production capacity needs.

- Stable Grinding: A multi-stage grinding structure ensures a consistent output of fine or granular cashew butter.

- Food-Grade Manufacturing Standards: The entire cashew butter line is constructed of food-grade stainless steel, meeting food safety requirements.

- Easy Maintenance and Cleaning: A well-designed structure minimizes downtime for cleaning, ensuring continuous production.

The cashew butter line is primarily used for the industrial production of cashew butter. By replacing parts of the production line, it can also be used for other nut butter products. Finished products can be widely used in nut butter factories, baking ingredients, nutritional foods, and catering raw material supply.

Technical Data

Related Products