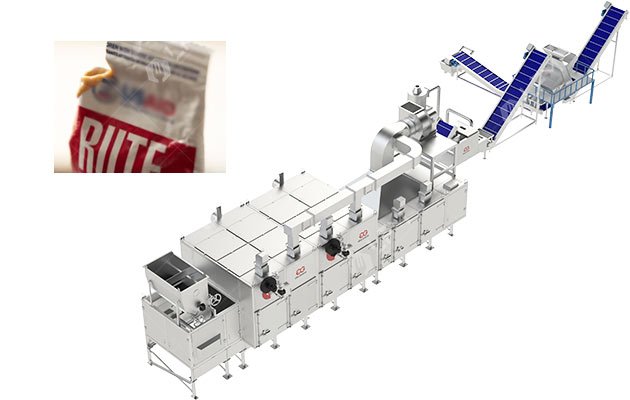

Safety Peanut Paste Line for RUTF & RUSF Production

- Material: Peanuts

- Capacity: 300-2000KG/H

- Loading Port:Qingdao Port

- Warranty:12 Months

- Quote Form:FOB, CIF, EXW, CFR

Features

Our company has specifically developed a peanut paste line for RUTF and RUSF production to address the global problem of malnutrition. This production line rigorously processes various high-energy nutritional products into safe, ready-to-eat products.

In the global fight against malnutrition, particularly in addressing severe acute malnutrition (SAM) and moderate acute malnutrition (MAM) in children, Ready-to-Use Therapeutic Food (RUTF) and Ready-to-Use Supplementary Food (RUSF) have become internationally recognized life-saving foods and crucial tools for nutritional intervention.

Why is a Dedicated RUTF Peanut Paste Line Needed?

- Traditional peanut butter production aims to meet daily consumption needs, while the requirements for RUTF and RUSF production lines are far more stringent:

- Nutrition and safety are paramount: The product is directly targeted at vulnerable, immunocompromised malnourished children. Any microbial contamination (such as aflatoxins, Salmonella) can be fatal. This line must have thorough sterilization and contamination control capabilities.

- Formula consistency is crucial: RUTF and RUSF are scientifically formulated "medicinal foods." The nutritional components (protein, fat, vitamins, minerals) of each batch must be absolutely uniform and stable. This places extremely high demands on raw material mixing and homogenization processes.

- Scale and efficiency to meet global demand: Global malnutrition problems are mainly concentrated in areas with relatively weak infrastructure, but the demand is high. The production line must be able to achieve continuous, large-scale, and automated production to ensure stable supply and reduce unit costs.

Therefore, a professional industrial-grade, safety-certified RUTF peanut paste line has emerged, precisely designed from the outset to meet these specific needs.

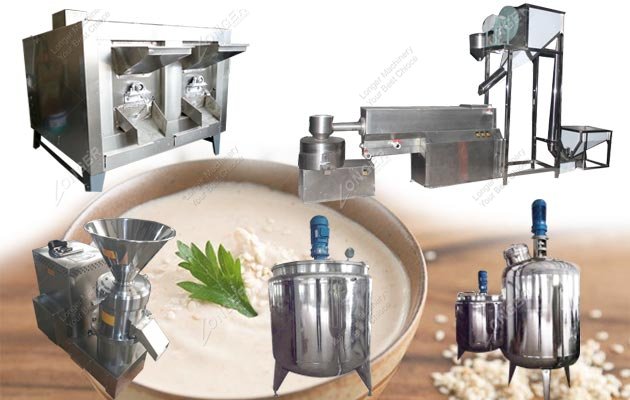

RUSF Peanut Paste Production Line Core Features:

- Intelligent Pre-treatment and Roasting System: Selected peanuts undergo optical sorting before entering a high-temperature roasting machine. This process activates aromas and efficiently degrades aflatoxins, ensuring raw material safety from the source.

- Ultra-fine Grinding and Homogenization System: Through multi-stage series grinding technology, peanuts are ground into an extremely fine paste. The system can integrate precise addition of micronutrient fortifiers, ensuring even nutrient distribution in RUTF and RUSF products.

- Aseptic Cooling and Sealed Filling System: After grinding, the peanut butter is rapidly cooled to prevent oxidation and then filled in a clean, sealed environment. It can be directly output as a finished base material or connected to subsequent mixing and molding processes.

- Fully Automated Process Control: The entire line is intelligently controlled by a central PLC, achieving continuous automated production from feeding to discharge. Key parameters are monitored and recorded in real time, ensuring product batch consistency and full traceability.

Frequently Asked Questions - RUTF Peanut Paste Line

Q1: Can this production line simultaneously produce both RUTF and RUSF base materials?

A: Absolutely. The core peanut roasting and grinding processes are the same. The production line features a modular design, allowing for flexible configuration of the nutrient fortification system during the homogenization stage. When producing RUTF, it operates according to the standard formula; when producing RUSF, the fortification process is activated, enabling multi-purpose use and high efficiency.

Q2: How effective is the RUTF and RUSF peanut paste line in controlling aflatoxin levels?

A: We provide a dual guarantee through "strict raw material selection + process control." First, the integrated high-precision sorting equipment effectively removes moldy kernels. Second, the core roasting process, under controlled temperature and time, has been proven to effectively degrade aflatoxin content. Combined with rigorous laboratory testing of the final product, we ensure that the finished product meets safety standards.

Q3: What are the production line's capacity and level of automation? Which regions are suitable for installation?

A: It is designed with scalable modular capacity, capable of processing from several hundred kilograms to multiple tons of peanuts per hour to accommodate varying production scales. RUTF peanut paste production line’s high level of automation minimizes manual intervention, making it especially suited for operation in regions with pressing nutritional needs yet limited technical workforce, such as parts of Africa and South Asia. We further support projects with comprehensive turnkey services—including facility layout planning, equipment commissioning, and operational training—to ensure seamless implementation and sustained production readiness.

Technical Data

Related Products