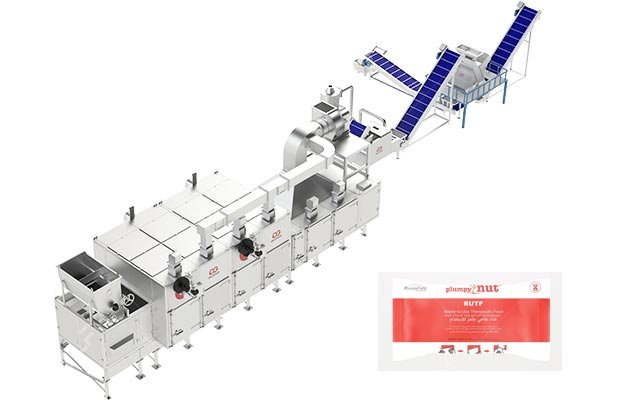

Automatic Plumpy Nut Production Line for Malnutrition

- Material: Peanuts

- Capacity: 500-1000KG/H

- Loading Port:

- Warranty:12 Months

- Quote Form:FOB, CIF, EXW, CFR

Features

The Plumpy Nut production line is a complete and automatic solution used for the manufacturing of Plumpy Nut. This production line is primarily developed for emergency nutrition supply programs targeting malnourished populations.

The production line uses professional, safe, and hygienic materials and undergoes rigorous testing. The resulting Plumpy Nut has evenly mixed nutrients and meets the approval of international organizations (USAID, UNICEF, etc.).

What Is a Plumpy Nut Production Line

This line refers to an integrated processing system that converts raw peanuts and fortified ingredients into homogeneous Plumpy Nut(RUTF peanut paste). The line covers the complete process from peanut roasting and peeling to grinding, mixing, emulsifying, and final paste handling.

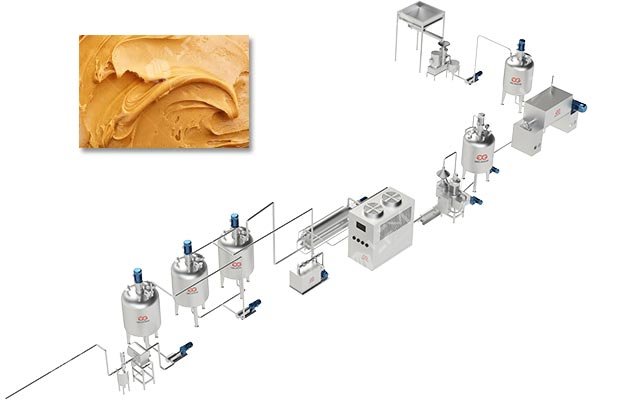

This type of production line is specifically designed for high-viscosity Plumpy Nut and fortified formulations that include vitamins, minerals, sugar, and vegetable oil. The goal is to achieve a smooth texture, accurate nutrient ratios, and long shelf stability without refrigeration.

Process Flow of Plumpy Nut Processing Line

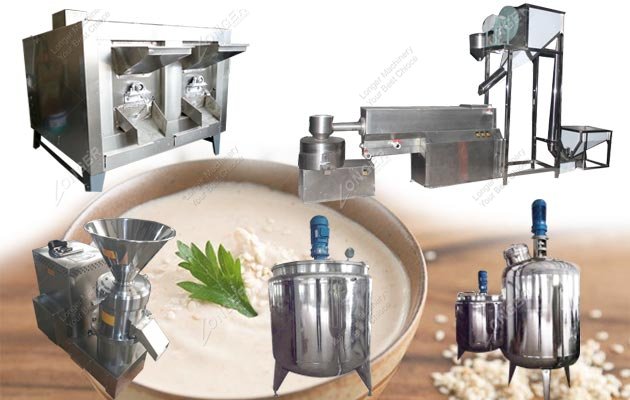

- Peanut Cleaning and Roasting: Raw peanuts are cleaned to remove impurities and then evenly roasted to enhance flavor and reduce moisture content.

- Cooling, Blanching, and Peeling: After roasting, peanuts are cooled and processed through blanching and peeling machines to remove skins and ensure a clean raw material base.

- Grinding and Paste Formation: The peeled peanuts are ground into fine peanut paste using high-performance grinding systems suitable for continuous industrial operation.

- Ingredient Dosing and Mixing: Vegetable oil, sugar, and vitamin-mineral premix are precisely dosed and mixed with peanut paste using high-viscosity mixers to achieve uniform nutrient distribution.

- Homogenization and Final Paste Handling: The Plumpy Nut is homogenized to ensure stable texture and then transferred for further processing, packaging, or storage.

Advantages of the Plumpy Nut Production Line

- Stable and Uniform Paste Quality: The processing system ensures consistent peanut paste texture and uniform distribution of nutrients, which is essential for therapeutic food applications.

- Precise Nutrient Dosing and Mixing: Equipped with accurate dosing and high-viscosity mixing systems, the line guarantees reliable formulation of vitamins, minerals, oil, and sugar in every batch.

- Flexible and Customizable Configuration: The Plumpy Nut processing line can be configured according to different capacity requirements, plant layouts, and project specifications.

- Automatic Control and Reliable Operation: The PLC control system allows stable, continuous operation with reduced manual intervention, improving production efficiency and process reliability.

- High Hygiene and Food Safety Standards: All equipment of Plumpy Nut line is manufactured from food-grade stainless steel and designed in accordance with GMP and HACCP requirements, supporting compliance with WHO and UNICEF guidelines.

Our automatic Plumpy Nut production line is developed with a focus on long-term stability, production efficiency, and international project requirements. With extensive experience in food processing equipment manufacturing, we provide customized solutions tailored to different capacities, layouts, and operational needs.

Technical Data

Related Products