Automatic RUTF Peanut Butter Production Line UNICEF Standard

- Material: Peanuts

- Capacity: 300-1000 kg/h

- Loading Port:Qingdiao Port

- Warranty:12 Months

- Quote Form:FOB, CIF, EXW, CFR

Features

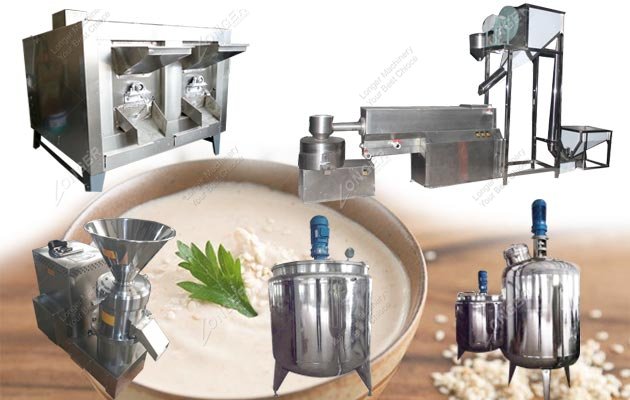

RUTF (Ready-to-Use Therapeutic Food) peanut butter is a high-energy, high-protein food designed specifically for malnourished children. Our RUTF peanut butter production line is an automated system that integrates raw material processing, grinding, blending, sterilization, and filling, efficiently producing RUTF peanut butter that meets UNICEF international standards. This equipment is widely used in food factories, nutritional supplement manufacturers, and international aid projects.

2. After peeling and sorting, the peanuts undergo multi-stage grinding to create a finely ground peanut butter.

3. Milk powder, sugar, vitamins, minerals, and other nutrients are added for a homogeneous blend.

4. Vacuum degassing and high-temperature sterilization ensure product safety.

5. Finally, the RUTF cans are packed into sachets using a fully automatic filling and packaging machine, ensuring consistent product quality and a secure seal.

This RUTF peanut butter production line can help you quickly enter the RUTF market. Please contact us for more information:

Email: serena@machinehall.com

WhatsApp/Mobile: +8615515597212

RUTF Peanut Butter Production Process:

1. Peanuts are carefully selected, cleaned, and roasted. The core peanut roasting machine utilizes an intelligent, constant-temperature roasting process to ensure uniform roasting and flavorful peanut butter.2. After peeling and sorting, the peanuts undergo multi-stage grinding to create a finely ground peanut butter.

3. Milk powder, sugar, vitamins, minerals, and other nutrients are added for a homogeneous blend.

4. Vacuum degassing and high-temperature sterilization ensure product safety.

5. Finally, the RUTF cans are packed into sachets using a fully automatic filling and packaging machine, ensuring consistent product quality and a secure seal.

Features of Automatic RUTF Production Line :

- High Automation: The entire process from loading, grinding, blending, sterilization, and filling is fully automated.

- High Grinding Fineness: Particles can reach micron levels, ensuring a smooth and delicate peanut butter texture. Available in 100, 200, and 300 mesh sizes.

- Precision Dosing System: Ensures consistent nutrient content in every batch, meeting international RUTF standards.

- Hygienic and Safety Design: The entire equipment is constructed of stainless steel and complies with HACCP and GMP requirements.

- Easy Cleaning: Utilizes CIP cleaning and SIP sterilization systems for efficient cleaning.

- Efficient Sterilization: Instantaneous high-temperature sterilization effectively extends product shelf life.

- Aseptic Packaging: Utilizes aseptic canning equipment to ensure a secure seal.

- Multiple Capacity Options: We offer a variety of capacity options, ranging from 100 kg/h to 1000 kg/h, supporting both small, medium, and large-scale production.

Advantages of the RUTF Peanut Butter Production Line:

Compliant with International Standards: Meets the stringent RUTF nutritional standards of the United Nations and the World Health Organization.- Reduced Labor Costs: High automation reduces reliance on manual labor, improving production efficiency while also reducing contamination.

- Stable and Reliable Quality: A precise automatic control system ensures consistent taste and nutritional value for each batch of RUTF.

- Easy to Clean and Maintain: The production line features a modular design and can be configured with a CIP cleaning system, making cleaning and equipment maintenance simple and quick.

- Adaptable to Diverse Market Needs: The PLC control system allows for rapid adjustment of recipes and output, making it suitable for the production of nutritious foods and aid supplies.

- Customization Supported: We can customize a perfectly matched RUTF peanut butter solution based on your recipe and plant layout.

This RUTF peanut butter production line can help you quickly enter the RUTF market. Please contact us for more information:

Email: serena@machinehall.com

WhatsApp/Mobile: +8615515597212

Technical Data

Related Products