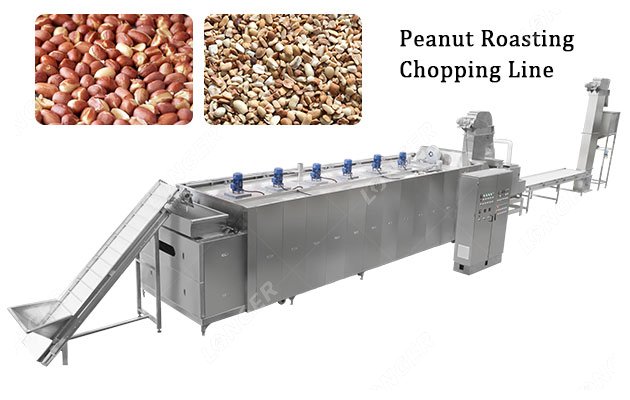

Automatic Peanut Roasting Chopping Line Machine 500 kg/h

- Material: Peanuts

- Capacity: 500 kg/h

- Loading Port:Qingdao Port

- Warranty:12 Months

- Quote Form:FOB, CIF, EXW, CFR

Features

The peanut roasting line can mainly complete the peanut roasting, peeling, selecting, chopping and screening processes, and is a fully automatic production line for producing crushed peanuts. The chopping line can also process almonds, cashews, macadamia nuts, and the like.

Continuous production, high production efficiency, labor saving, uniform roasting, fast cutting speed and high quality.

Process Flow:

Peanuts (cashew nut, almond, macadamia nut) - lifting - roasting - peeling - selecting - chopping - sereening - packaging

Introduction of Peanut Roasting Line Equipment:

1. Automatic Peanut Roasting Machine

The equipment has roasting and cooling functions and is suitable for continuous production of roasted nuts. The roasting part exchanges heat energy with the material through the hot air passing through the material layer to achieve high-quality baking; the cooling part exchanges heat energy with the material through the cold air passing through the material layer to achieve rapid cooling of the material.

Advantages of Peanut Roasting and Cooling Machine

- Effectively maintain roasting temperature, well sealed, prevent heat loss. Ideal roasting effect and heating aralso can avoid accidental scald.

- Hot air convection roasting: bigea, roasting uniformly, more than 250 pcs of air outlet to make sure uniform roasting effect.

- Low Noise: Fan impeller adopts multi-wing impeller, with low noise.

- Intelligent digital display, precise temperature control: temperature adjust range is wide. The roasting temperature can be adjusted according to different material.

- Better cooling effect: two big fan to cool material after roasting.

2. Peanut Peeling Machine

This machine is mainly used for the peeling and processing of peanut kernels. The peanuts are divided into half by the extrusion of two rubber rollers and differential rubbing. During the vibration conveying process, the red skin is separated by the fan, and the germ is sieved.

3. Peanut Chopping Machine

The whole set of equipment consists of elevator, chopper and screening machine. Each equipment operates independently and is controlled separately, which effectively improves the operating efficiency and maximizes the operating efficiency of the equipment.

The crushed peanuts have uniform particle size, beautiful appearance, less material consumption, no oiliness, and the size of crushed peanuts can be adjusted.

Technical Data

| No. | Name | Power(kw) | Dimension(mm) |

| 1 | Lifting Machine | 0.75 | Height:2000mm |

| 2 | Roasting and Cooling Machine |

4.4kw Gas Consumption: 10-12KG/H |

8500*2250*2600 |

| 3 | Lifting Machine | 0.75 | Height:2000mm |

| 4 | Peeling Machine | 1.5+0.75 | 1800*750*1300 |

| 5 | Picking Belt(4m) | 0.75 | 4000*700*1000 |

| 6 | Peanut Chopping Machine | 3.7 | 2080*1000*1700 |

| 7 | Vibrating Screen | 0.36 | 2400*1120*1020 |

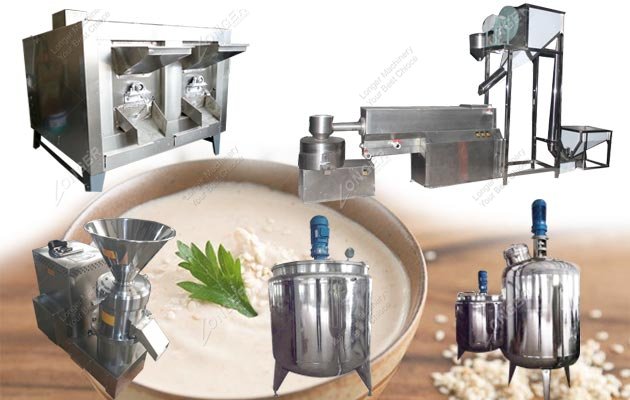

Related Products