1 T/H Peanut Butter Manufacturing Machine Plant Automatic

- Material: Peanuts

- Capacity: 1 T Per Hour

- Loading Port:Qingdao Port

- Warranty:12 Months

- Quote Form:FOB, CIF, EXW, CFR

Features

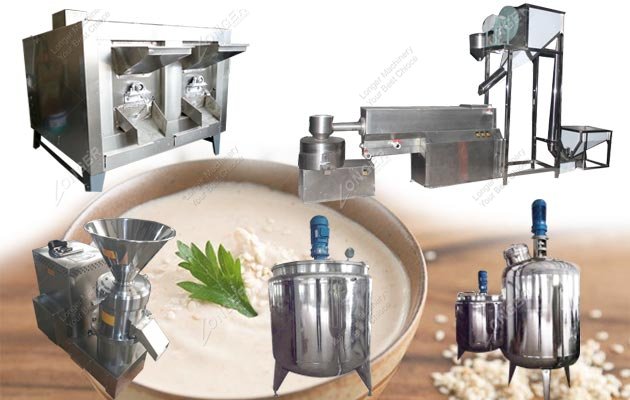

This set of peanut butter manufacturing machine is highly automated, and can realize continuous production from peanut cleaning to butter filling. The whole line has advanced technology, and the output can reach 1 ton per hour. We can meet the customized needs of large peanut butter factories.

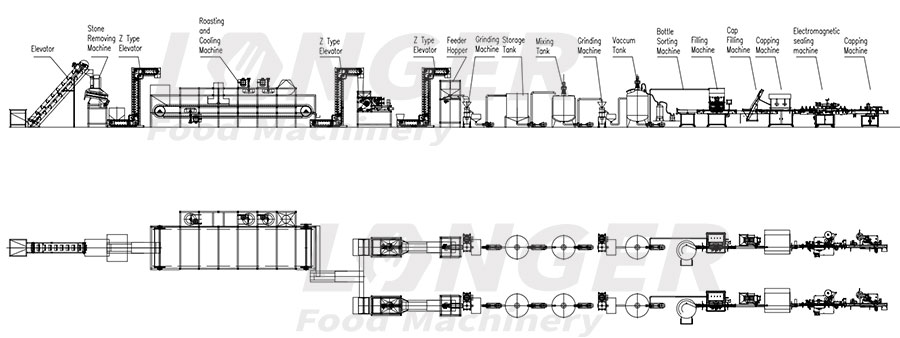

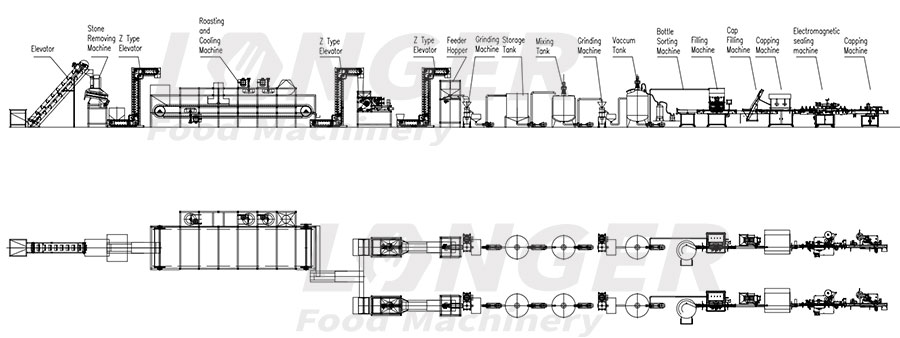

Process Flow of Peanut Butter Manufacturing Plant:

Process Flow of Peanut Butter Manufacturing Plant:

Peanut kernels → cleaning → roasting → cooling → peeling → grinding sauce → mixing → vacuum degassing → filling → capping → labeling → finished peanut butter

2. Peanut Roasting Machine: with roasting and cooling functions, chain plate conveying structure, realizing continuous and high-quality roasting.

3. Peanut Peeling Machine: The machine has a high degree of automation, and can realize the three functions of peeling, kernel peel separation and sprout removal from material feeding to discharging.

4. Peanut Butter Grinding Machine :Grinding the whole peanut into butter. It is widely used in many industrial such as Cocoa Butter, Tahini, Hummus and so on.

5. Storage Tank: After grinding the Paste, the Peanut Butter enters this tank for storage, and will add cover to Prevent exposure to air.

6. Mixing Tank: You can add some Peanuts Dices in this part, it have the mixing function, it can make the Crunchy Peanut Butter.

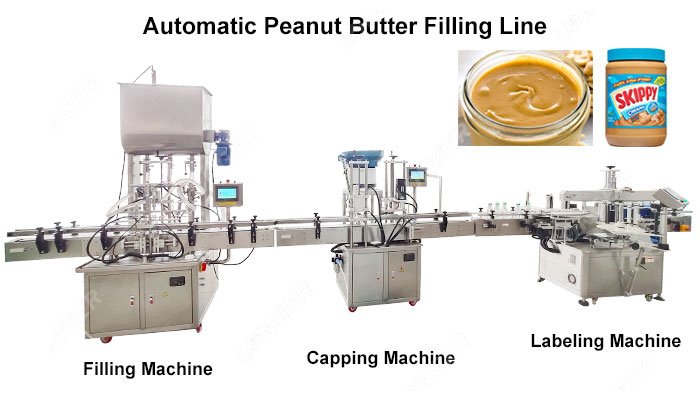

7. Peanut Butter Filling Machine: For filling various liquids, multiple filling nozzles can be customized according to production needs, with high filling accuracy.

8. Cappling Machine: achieve automatically feeding caps and cap bottles,save labor and reduce production error.

9. Labeling Machine: Automatically complete labeling, with high labeling accuracy, high efficiency, and accurate labeling position. Additional production counting function.

List of Peanut Butter Making Machines:

1. Peanut Stone Removing Machine: Use the principle of specific gravity to separate the material from the stone. Stable operation, low vibration, low noise, and good stone removing effect.2. Peanut Roasting Machine: with roasting and cooling functions, chain plate conveying structure, realizing continuous and high-quality roasting.

3. Peanut Peeling Machine: The machine has a high degree of automation, and can realize the three functions of peeling, kernel peel separation and sprout removal from material feeding to discharging.

4. Peanut Butter Grinding Machine :Grinding the whole peanut into butter. It is widely used in many industrial such as Cocoa Butter, Tahini, Hummus and so on.

5. Storage Tank: After grinding the Paste, the Peanut Butter enters this tank for storage, and will add cover to Prevent exposure to air.

6. Mixing Tank: You can add some Peanuts Dices in this part, it have the mixing function, it can make the Crunchy Peanut Butter.

7. Peanut Butter Filling Machine: For filling various liquids, multiple filling nozzles can be customized according to production needs, with high filling accuracy.

8. Cappling Machine: achieve automatically feeding caps and cap bottles,save labor and reduce production error.

9. Labeling Machine: Automatically complete labeling, with high labeling accuracy, high efficiency, and accurate labeling position. Additional production counting function.

Advantages of Automatic Peanut Butter Manufacturing Machine

- Fuly alutomatic and continuous production will help you greatly improve your work efficiency.

- Multi-capacity production lines are optional, such as 200kg/h, 500 kg/h, 1 t/h and so on.

- The closed and unmanned operation of the entire line ensures that the quality of peanut butter meets the conditions for food hygiene production.

- The whole set of equipment can be customized according to your needs to meet the needs of mass production.

Technical Data

| No | Name | Dimension(mm) | Quantity |

| 1 | Stone Removing Machine | 1350*1050*1800 | 1 |

| 2 | Color Sorting Machine | 1648*1587*1968 | 1 |

| 3 | Roasting and Cooling Machine (Gas Heating) | 11500*2250*2600 | 1 |

| Roasting and Cooling Machine (Electric Heating) | 11500*2250*2600 | ||

| 4 | Peeling Machine with Dust Collecting Device | 2000*800*2200 | 2 |

| 5 | Peanut Butter Grinding Machine JMS-180 Double Type | 830*490*1120 | 2 |

| 6 | Storage Tank | 1000*1000*1200 | 2 |

| 7 | Mixing Tank | 1000*1000*2000 | 2 |

| 8 | Vacuum Tank | 1000*1000*2400 | 2 |

| 9 | Sealed Storage Tank | 1000*1000*1800 | 2 |

| 10 | Bottles Sorting Machine | / | 2 |

| 11 | Double Nozzles Filling Machine for Peanut Butter | 2000(Elevator)*1150*1850 | 2 |

| 12 | Capping Machine | 2000(Elevator)*1150*1650 | 2 |

| 13 | Electromagnetic Sealing Machine | 900*310*1040 | 2 |

| 14 | Labeling Machine | 2000(Elevator)*1150*1650 | 2 |

Related Products