1 T Automatic Hazelnut Processing Machine Line

- Material: Hazelnuts

- Capacity: 1000 kg/h

- Loading Port:Qingdao Port

- Warranty:12 Months

- Quote Form:FOB, CIF, EXW, CFR

Features

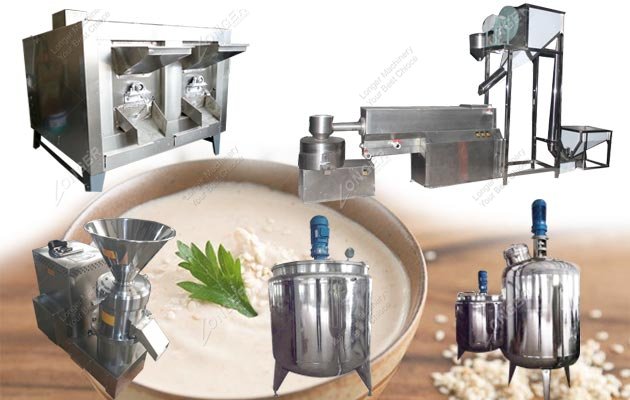

The hazelnut processing machine is composed of a three-stage hazelnut cracking machine, a shell and kernel separator, and a classifier. Large output, automatic production, clean shelling, high integrity rate.

This set of equipment can also be used for processing almonds, palm kernels, etc., with multiple uses.

The Composition of the Hazelnut Processing Line:

(1) Lifting machine: The raw material hazelnut has been entered into the sieve selection machine (flat screen or roller screen selection) by the lifting machine.

(2) Hazelnut shelling machine: The hazelnuts are divided into three levels or above, and then enter three independent shelling machines through the hopper. The husks of hazelnuts are broken by squeezing. (The shelling gap is adjusted and matched according to the size of the hazelnuts to achieve clean shelling and ensure the integrity of the nuts.)

(3) Shell and kernel separator: The hazelnut shells and kernels enter two shell and kernel separators respectively to separate the shells and kernels.

(4) Picking belt: The shelled hazelnuts are manually picked to remove the uncleaned hazelnuts, and then sent to the elevator.

(5) Hazelnut kernel grading machine: Grading the hazelnut kernels into three sizes.

Advantages of Hazlenut Processing Machine

- With an output of 800-1000 kg/h, it is an ideal choice for large hazelnut shelling processing plants to improve efficiency and reduce costs.

- Realize the fully automatic and continuous processing of hazelnuts and reduce labor costs.

- The shelling rate of hazelnuts is as high as 98%, and the completeness rate is high.

- Easy to clean, easy to operate and maintain.

Instructions for Use of Hazelnut Processing Equipment:

1. When all the machines are set up, they need to be fixed, and each device needs to be fixed with the soles of the feet.

2. The three-level shelling machine of the host is fixed first, and the other equipment is adjusted according to the positioning of the shelling machine, and fixed after the adjustment is completed.

3. When all the equipment is connected, it need test it first without almond. If that is no problem, you need to adjust the gap of the three level shelling machine.

4. Because the height of the Three-level cracking equipment is too high, it cannot be directly packed into the cabinet. It is disassembled and transported.

Technical Data

| Name | Power(kw) | Dimension(mm) | Qty |

| Feeding Hopper and Elevator | 0.75 | 2800*600*2600 | 1 |

| Hazelnut Cracking Machine | 8 | 2200*1750*2500 | 1 |

| Elevator | 0.75 | 1800*600*1600 | 1 |

| Kernel and Shell Separating Machine | 2.2 | 2500*750*1500 | 2 |

| Picking Line | 0.75 | 6000*800*1000 | 1 |

| Elevator | 0.75 | 1800*600*1600 | 1 |

| Hazelnut Kernel Grading Machine | 1.1 | 1900*800*1400 | 1 |

Related Products