Palm Kernel Cracking Crushing Machine|Chestnut Processing Equipment Plant

- Material: palm kernel,hazelnut

- Capacity: 1 t/h

- Loading Port:Qingdao Port

- Warranty:12 Months

- Quote Form:FOB, CIF, EXW, CFR

Features

The palm processing equipment is mainly used to crush palm kernel and separate shell kernel. The shell cracking machine is also suitable for processing almond, hazelnut, chestnut and so on nuts.

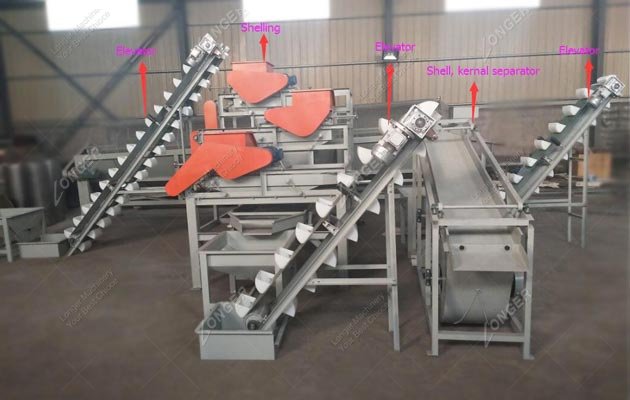

Main Components of Palm Kernel Crushing Processing Machine

Main Components of Palm Kernel Crushing Processing Machine

1. Belt conveyor machine

The hopper picks up the material from the storage below, and as the conveyor belt or chain is lifted to the top, it turns around the top wheel and flips downwards. The bucket elevator pours the material into the receiving tank. Belt conveyor belt elevator belt is generally used rubber belt. It can be combined with other ancillary equipment to form a continuous or intermittent automated production line, and it is easy to maintain, easy to disassemble, and easy to clean.

2. Palm kernel and chestnut cracking machine

The shell crushing equipment is composed of a lifting machine and three levels of shelling processing. By adjusting the gap between the processing rollers at all levels, palm kernel and chestnut can be processed at one time without grading. Palm has a low crushing rate and is an ideal processing equipment for paim, hazelnut, chestnut, almonds, peach kernels, and the like. Cost-effective, save manpower, material resources and financial resources.

3. Palm and hazelnut shell kernel separator

The shell kernel separator is used for apricot, palm, hazelnut, chestnut, walnut and cashew kernel sheller. After shelling, palm kernel and shell are separated by shell kernel separator. It can also be used to separate shell nuts after shelling. The machine uses the difference between the specific gravity of the shell and the core and the levitation speed, and promotes the separation between the shell kernels by means of the airflow passing through the gaps between the particles. This product uses a single (double) fan, separation effect is good, high yield, is an ideal shell kernel separation equipment.

Service for Chestnut Cracking Processing Machine

1. Pre-sale service:

1. Pre-sale service:

Accept customer consultation, determine the scale of operations according to customer needs, and provide plant construction plans;

Provide customers with project design, process design, suitable for the formulation of your machine equipment purchase plan, timely provide relevant technical documents for customers; design and manufacture products according to your special needs, and conduct preliminary design and construction for your training technical operators design.

2. Sales service:

The company sent technicians to the site to guide the installation and commissioning of the equipment and train operators.

3. After-sale service

The company has a dedicated telephone line for technical services to answer in a timely manner for the majority of users and eliminate many difficult problems in the production process.

Technical Data

| Hoister |

Size: 0.6*0.6*6.5m Power: 0.75kw Voltage: 380v/50hz |

| Horizontal sieve grading machine |

Three Level Size: 3.2*1.1*2.5m Material: carbon steel Power: 1.5kw Voltage: 380v/50hz |

| Distribution Hopper |

Size: 2*0.7*1.3m Feed almond into three shelling machine |

| Three Sheller Machine |

Single Sheller Machine: Size: 3.5*0.9*1.3m Power: 3kw Voltage: 380v/50hz Weight: 280kg |

| Three-level Shelling Machine |

Three-level Almond Sheller Machine: Output:1000kg/h Power: 6.75KW Voltage: 380V Size: 3.2*2.1*2.6m Weight: 2100kg |

| Kernel shell Separator |

Size: 3.2*0.9*1.6m Power:1.5kw/3kw Voltage: 380v/50hz |

| Picking Line |

Size: 5*0.6*1.5 Power: 0.75KW Voltage: 380V/50HZ |

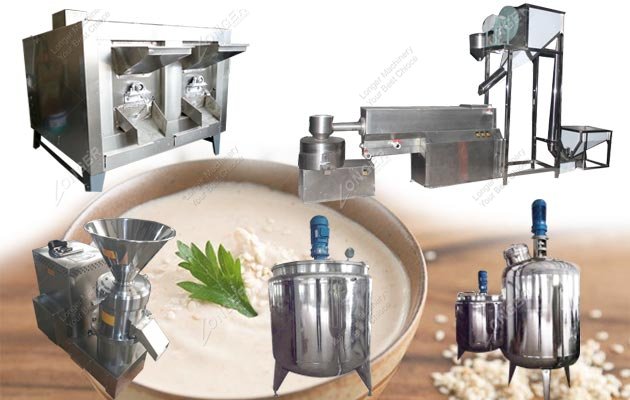

Related Products