500 KG Automatic Cocoa Chocolate Liquor Production Process Line

- Material: Cocoa Bean

- Capacity: 500 KG / H

- Loading Port:Qingdao Port

- Warranty:12 Months

- Quote Form:FOB, CIF, EXW, CFR

Features

The automatic cocoa liquor production line can produce 500 kg of cocoa liquor (chocolate liquor) per hour from raw cocoa beans. The final product is smooth, refined, fluid chocolates liquor that is an important ingredient in making chocolate and cocoa products, such as cocoa powder, cocoa butter, dark chocolate, chocolate bar, chocolate chips and so on.

Chocolate liquor production process: Stone removal - roasting - cooling - peeling - grinding sauce - cooling - insulation storage - tempering

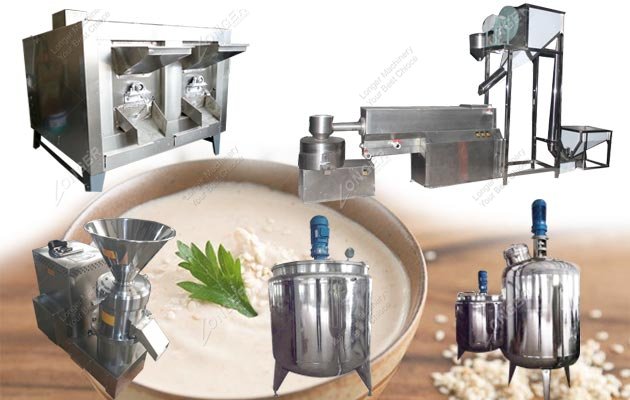

Main Machines of 500 KG Cocoa Liquor Production Line

1. Cocoa Bean Stone Removing Machine

Remove all kinds of foreign substances doped in cocoa beans, such as stones, dust, sediment, leaves, etc.

2. Cocoa Roasting Machine

The moisture content of cocoa beans is reduced to 5-7% at 120 C, which releases the flavor of chocolate and is also conducive to the next peeling process.

3. Cocoa Peeling Machine

Removal of cocoa skin and germ to obtain cocoa kernels, also called cacao nibs.

4. Cocoa Grinding Machine

The double colloid mill is used to increase the fineness of the paste. The basic working principle of colloid mill is shearing, grinding and high-speed stirring. The machine is also suitable for making various nuts butter and bean paste.

5. Storage Tank

Insulation storage slurry to adapt to continuous production. It has various functions such as cooling, heating, heat preservation, stirring, degassing, deodorization and dehydration.

6. Chocolate Tempering Machine

The machine can strictly control the different temperatures required for the chocolate paste in each stage of the process, ensuring the quality of the chocolate products, making the natural flavor of the chocolate more concentrated, the mouth is lubricated, the color is bright, and the preservation is good.

Showing Video of Fully Automatic Chocolate Liquor Production Line

Application of Cocoa Liquor (Chocolate Liquor)

We can separate cocoa liquor into cocoa solids and cocoa butter (roughly the same ratio), or cool and mold them into raw chocolate. It is mainly used (usually with other cocoa butters) to make chocolate.

Chocolate liquor production process: Stone removal - roasting - cooling - peeling - grinding sauce - cooling - insulation storage - tempering

Main Machines of 500 KG Cocoa Liquor Production Line

1. Cocoa Bean Stone Removing Machine

Remove all kinds of foreign substances doped in cocoa beans, such as stones, dust, sediment, leaves, etc.

2. Cocoa Roasting Machine

The moisture content of cocoa beans is reduced to 5-7% at 120 C, which releases the flavor of chocolate and is also conducive to the next peeling process.

3. Cocoa Peeling Machine

Removal of cocoa skin and germ to obtain cocoa kernels, also called cacao nibs.

4. Cocoa Grinding Machine

The double colloid mill is used to increase the fineness of the paste. The basic working principle of colloid mill is shearing, grinding and high-speed stirring. The machine is also suitable for making various nuts butter and bean paste.

5. Storage Tank

Insulation storage slurry to adapt to continuous production. It has various functions such as cooling, heating, heat preservation, stirring, degassing, deodorization and dehydration.

6. Chocolate Tempering Machine

The machine can strictly control the different temperatures required for the chocolate paste in each stage of the process, ensuring the quality of the chocolate products, making the natural flavor of the chocolate more concentrated, the mouth is lubricated, the color is bright, and the preservation is good.

Showing Video of Fully Automatic Chocolate Liquor Production Line

Application of Cocoa Liquor (Chocolate Liquor)

We can separate cocoa liquor into cocoa solids and cocoa butter (roughly the same ratio), or cool and mold them into raw chocolate. It is mainly used (usually with other cocoa butters) to make chocolate.

Technical Data

| No. | Name | Power(KW) | Size(mm) |

| 1 | Stones Remover Machine |

Host power: 0.55KW Fan power: 3KW Hoist power: 0.75KW |

1300*660*1630 |

| 2 | Cacao Grader Machine | 0.75kw | 1500*800*1250 |

| 3 | Cocoa Bean Roaster |

Heating power: 36-44kw/380v Transmission Power: 2.2KW |

2900*2100*1650mm |

| 4 | Cooling Machine | 2.2KW,380V | 3000*1100*850mm |

| 5 | Cocoa Bean Peeling Machine | 1.5kw+0.75kw | 1800*750*1300mm |

| 6 | Cocoa Bean Grinder | 7.5kw | 990*440*1100 |

| 7 | Liquor Storage Tank: | 1.1kw | 750*750*1500mm |

| 8 | Heated Stirring Tank | 3KW+12KW | Diameter:1m Height:1.9m |

Related Products