Industrial Chocolate Chip Making Machine Production Line for Sale

- Material: Chocolate chips

- Capacity: 60-200 kg/h

- Loading Port:Qingdao Port

- Warranty:12 Months

- Quote Form:FOB, CIF, EXW, CFR

Features

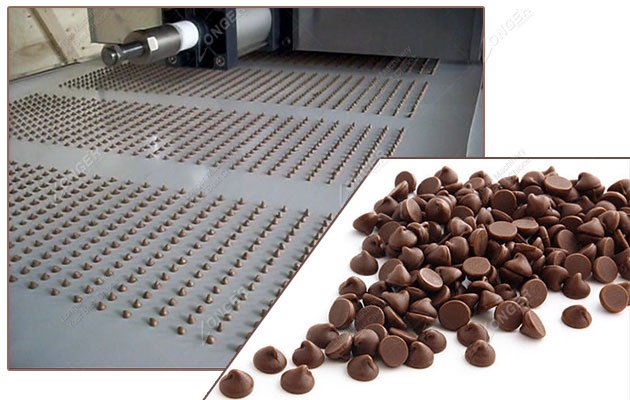

Industrial chocolate chip making machine is a special equipment for producing chocolate and milk chocolate drops products. It can produce different shapes and weights of 0.1-5g chocolate chips products, such as chocolate chips with tails at the top (such as water drops), and buttons shape chocolate chips( without tails). Multi-functioanl.

Working Principle of Chocolate Chips Making Machine:

1. The lower end face of the blanking chamber is provided with 60~150 discharging holes. The number of discharge holes at the bottom of the blanking chamber is more, the smaller the diameter is, the smaller the chocolate particles are dripped, the more the number of drips is, and the higher the efficiency is.

2. During the pouring process, the chocolate slurry is dripped onto the belt through a plurality of dispersed discharge holes, and then cooled and formed.

Industrial Chocolate Chips Production Line Video:

Features of Industrial Chocolate Chip Depositor Machine:

Working Principle of Chocolate Chips Making Machine:

1. The lower end face of the blanking chamber is provided with 60~150 discharging holes. The number of discharge holes at the bottom of the blanking chamber is more, the smaller the diameter is, the smaller the chocolate particles are dripped, the more the number of drips is, and the higher the efficiency is.

2. During the pouring process, the chocolate slurry is dripped onto the belt through a plurality of dispersed discharge holes, and then cooled and formed.

Industrial Chocolate Chips Production Line Video:

Features of Industrial Chocolate Chip Depositor Machine:

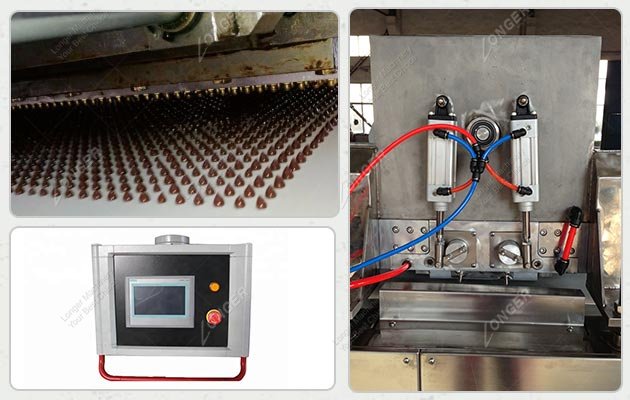

- The number and distribution of discharge holes are very reasonable, and multiple particles can be dripped at one time, with high efficiency and uniform particles.

- The best size cylinder and double insulation water circulation system can effectively control the temperature of dropping slurry.

- The cylinder and mixer are easy to remove and clean.

- The chocolate drop depositor machine is controlled by Siemens PLC with touch screen, so it will be more exact.

- The depositor is based on the existing casting machine, which improves the distribution plate structure and has low cost.

- The operation and contact parts of the material are made of 304 stainless steel, which is safe and hygienic and has long service life.

Technical Data

| Model | LG-CDJ600 | LG-CDJ800 | |

| Width of conveyer belt (mm) | 600mm | 800mm | |

| Speed of conveyer belt (m/minute) | 0 - 3 | 0 - 3 | |

| Depositing speed (times/minute) | About 15 | About 15 | |

| Capacity (kg/hour) | If 0.1g chips | 60 kg/hour | 80 kg/hour |

| If 1g chips | 150 kg/hour | 200kg/hour | |

| Power of Compressor | 5HP | 8HP | |

| Brand of Compressor | Emerson | Emerson | |

| Temperature in Cooling Tunnel | 5 - 10℃ | 5 - 10℃ | |

| Power (kw) | 12 | 18 | |

| Weight (kg) | 2500 | 2600 | |

| Size(L*W*H, mm) | 12000*1050*1600 | 12000*1250*1600 | |

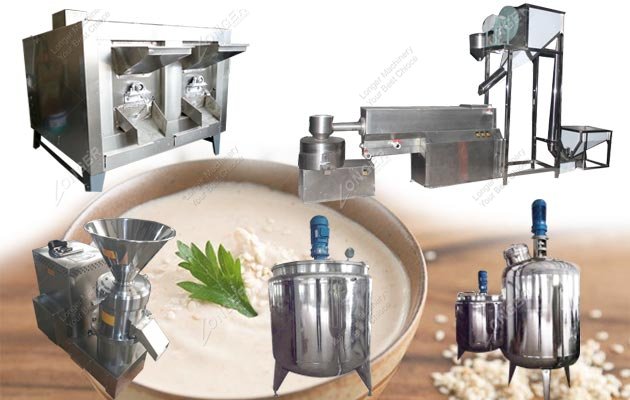

Related Products