Mesh Belt Chocolate Chips Depositing Machine Price

- Material: Chocolate Chips

- Capacity: 60-120 kg/h

- Loading Port:Qingdao Port

- Warranty:12 Months

- Quote Form:FOB, CIF, EXW, CFR

Features

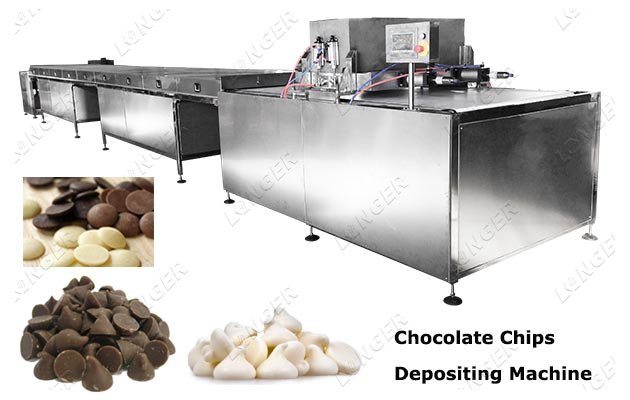

The chocolate chips depositing machine is a professional equipment for producing small granular chocolate (droplet or button chocolate chips). Mesh belt conveyor, stainless steel, PLC control, fully automatic production.

Structure of Chocolate Chip Depositor:

The machine mainly consists of a chip depositing device and a cooling tunnel. The dripping topping drips the chocolate sauce. Droplet-shaped, button-shaped particles fall on the conveyor belt, and then the product is transported to the cooling tunnel for cooling and automatic falling off.

Working Video of Chocolate Chip Depositor Machine

Features of Chocolate Chips Depositing Machine

Related Product: Chocolate Chips Production Line

Structure of Chocolate Chip Depositor:

The machine mainly consists of a chip depositing device and a cooling tunnel. The dripping topping drips the chocolate sauce. Droplet-shaped, button-shaped particles fall on the conveyor belt, and then the product is transported to the cooling tunnel for cooling and automatic falling off.

Working Video of Chocolate Chip Depositor Machine

Features of Chocolate Chips Depositing Machine

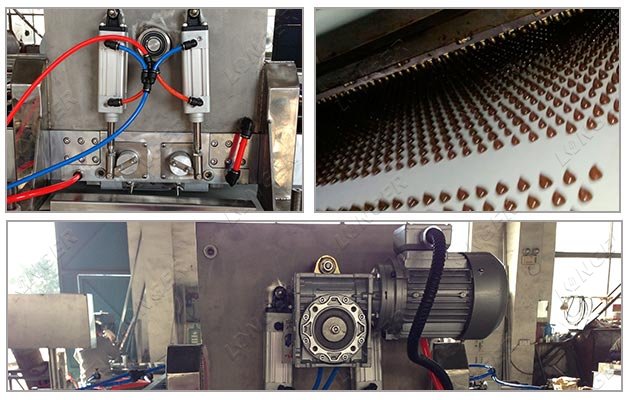

- Accurate measurement. Servo-driven or air-cylinder driven drip pouring piston, increase drip pouring accuracy.

- Health and Safety. All parts in contact with the material are made of 304 stainless steel.

- The cooling channel temperature is automatically controlled and can be set freely according to production needs.

- Cooling is performed in a cycle, which reduces the loss of cooling air and improves the efficiency of the cooling system.

- PLC touch screen control system, easy to operate.

Operational matters needing attention:

- When depositing is started, the check bolt of the main motor should be loosened.

- Before adding the chocolate paste, check that no other items have fallen in the hopper. Chocolate syrup should be preheated to 35-40 ° C before being added to the hopper.

- Automatic cooling channel temperature control. The maximum and minimum temperatures can be set according to production needs.

- After the production is completed, open the cleaning button to clean the valve and hopper.

- After cleaning, blow the two parts with compressed air to prevent water from entering.

- The surface of the conveyor belt should also be cleaned with a suitable food-grade detergent.

Related Product: Chocolate Chips Production Line

Technical Data

| Model | LG-CDJ600 | LG-CDJ800 | LG-CDJ1000 | LG-CDJ1200 |

|

Width of mesh belt (mm) |

600mm | 800mm | 1000mm | 1200mm |

| Particle weight(g) | 0.1 - 3 | 0.1 - 3 | 0.1 - 3 | 0.1 - 3 |

| Brand of Compressor | Emerson | Emerson | Emerson | Emerson |

|

Temperature in Cooling Tunnel |

0 - 10℃ | 0 - 10℃ | 0 - 10℃ | 0 - 10℃ |

|

Length of Cooling Tunnel(m) |

10 | 18 | 18 | 18 |

Related Products