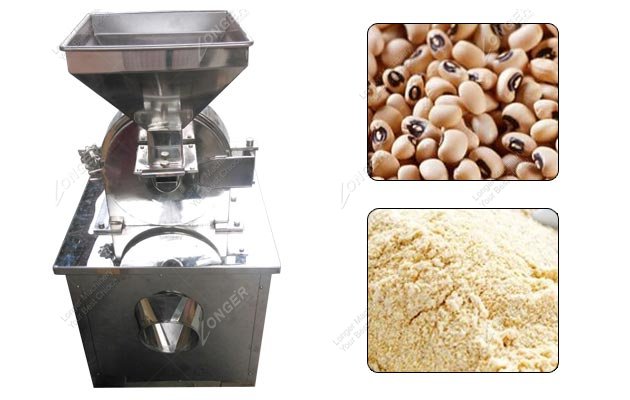

Black Eyed Beans Grinding Machine|Cowpea Grinder Mill

- Material: black eyed bean,cowpea

- Capacity: 100-500 kg/h

- Loading Port:Qingdao Port

- Warranty:12 Months

- Quote Form:FOB, CIF, EXW, CFR

Features

Working Principle of Black Eyed Beans Grinding Machine:

This powder grinding machine adopts impact crushing method. When the material enters the crushing chamber, it is impacted by six movable hammers, which are swivel at high speed. The black eyed bean is crushed by the impact between the gear ring and the material. The crushed bean powder enters the powder bag through the sieve hole with the help of the air flow, leaving no residue. The machine has the advantages of high efficiency, low noise, reliable working performance and product quality, safe operation, small drug hygiene and low loss.

Application of Black Eyed Pea Grinder

This machine is widely used in pharmaceutical, food(bean powder, spcies, powder, sugar and salt powders), chemical and other industries crushed material, a very wide range of uses.

Features of Cowpea Grinder Machine:

1. The grinder machine can reduce the noise effectively by using the completely closed silencing structure.

2. It has strong crushing capacity, low energy consumption and relatively small relative fineness of the finished powder or flour.

This powder grinding machine adopts impact crushing method. When the material enters the crushing chamber, it is impacted by six movable hammers, which are swivel at high speed. The black eyed bean is crushed by the impact between the gear ring and the material. The crushed bean powder enters the powder bag through the sieve hole with the help of the air flow, leaving no residue. The machine has the advantages of high efficiency, low noise, reliable working performance and product quality, safe operation, small drug hygiene and low loss.

Application of Black Eyed Pea Grinder

This machine is widely used in pharmaceutical, food(bean powder, spcies, powder, sugar and salt powders), chemical and other industries crushed material, a very wide range of uses.

Features of Cowpea Grinder Machine:

1. The grinder machine can reduce the noise effectively by using the completely closed silencing structure.

2. It has strong crushing capacity, low energy consumption and relatively small relative fineness of the finished powder or flour.

3. This grinding machine is equipped with a cooling device to reduce the temperature of the machine and work more smoothly.

4. It is made of 304 stainless steel. It has strong corrosion resistance and corrosion resistance. The grinding mill is suitable for processing advanced and corrosive materials.

Instructions

1. Universal grinder for the entire box, unboxing, moved to the appropriate location, place a smooth, power, you can try.

2. Before use should check the transmission parts are loose and other abnormal phenomenon, the direction of the machine should be consistent with the direction of the arrow.

3. Use no-load test for 1-2 minutes, until no abnormal phenomenon can be expected to feed, feed should gradually increase the volume of traffic, and observe the motor power consumption and operation at any time until the balance of feeding and power supply is working properly, Dead cut off the gate, to work. Midway as the material is too wet, too much sticky sticky, affecting the powder, the material should be dried or replaced thicker sieve. Replace the sieve simply open the front cover can be carried out, install the front cover should pay attention to the elastic hand wheel on both sides, to ensure that the front cover and the chassis sealed. Stop feeding before stopping, let the machine run for 5-20 minutes before stopping, in order to reduce the residual material.

Technical Data

| Model | LG-S40B | LG-S50B |

| Capacity(kg/h) | 100-400 | 200-500 |

|

Crushed powder fineness(mesh) |

20-120 | 20-120 |

| Cutter diameter(mm) | 350 | 500 |

| Host power(kw) | 11 | 15 |

| Dimension(mm) | 850*700*1450 | 800*950*1550 |

| Weight(kg) | 440 | 560 |

Related Products