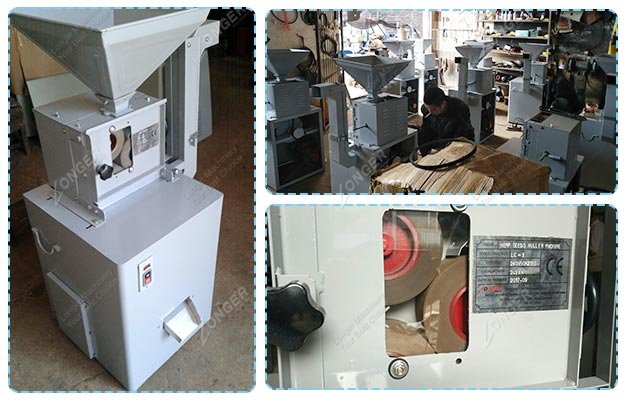

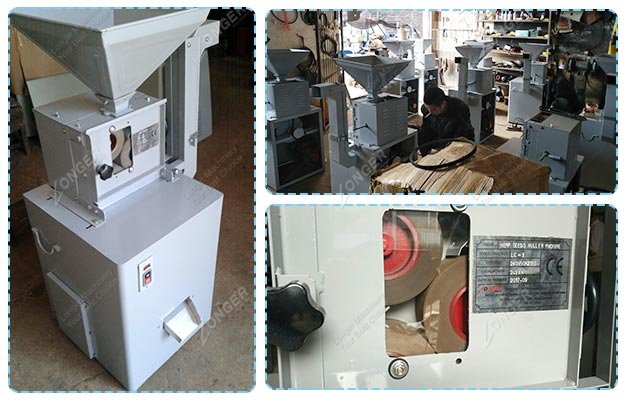

300 KG Friction Spelt Einkorn Dehulling Machine for Sale

- Material: spelt wheat,einkorn

- Capacity: 300-400kg/h

- Loading Port:Qingdao Port

- Warranty:12 Months

- Quote Form:FOB, CIF, EXW, CFR

Features

The einkorn dehulling machine adopts rubber roller friction structure to remove the einkorn's husk, spelt wheat and rice hulls. It is one of the main processing machinery for grain flour production.

Application of Spelt Dehuller for Sale

It can be used to process spelt wheat, einkorn wheat, rice, hemp seed, oats, paddy etc grains. The hulling machine is improved in the process of the traditional machine, avoid the destruction of the smooth surface to improve einkorn wheat and spelt separation effect, maintain high and stable rate of shelling.

Application of Spelt Dehuller for Sale

It can be used to process spelt wheat, einkorn wheat, rice, hemp seed, oats, paddy etc grains. The hulling machine is improved in the process of the traditional machine, avoid the destruction of the smooth surface to improve einkorn wheat and spelt separation effect, maintain high and stable rate of shelling.

Structure of Friction Spelt Dehulling Machine

The small and medium sized spelt dehuller not only inherits the structure and function of the traditional large hulling machine, can remove the wheat shell, reducing grain and skin damage, try to keep the rice complete, and reduce the volume and energy consumption of the traditional models, provides a convenient and practical for small commercial rice sheller.

Features of Einkorn Dehulling Machine

Features of Einkorn Dehulling Machine

- Wheat sample size can be set according to need, easy to operate.

- Automatic continuous feeding, shelling, separation effect is good.

- Polyurethane rubber roller, after the shelling of einkorn wheat, wheat has no damage, broken rice rate is low.

- The spelt wheat dehulling rate can reach to 99%.

- Durability of polyurethane rubber roller is good, the motor adopts DC stepless speed regulation, and the service life is long.

- The distance between the rubber rollers and the size of the wind can be adjusted to ensure that all the wheat is stripped.

Reasons for low hulling rate and solutions:

Q:The gap between the two rubber rollers is too large.

A:Adjust the gap between 0.5 and 0.8 mm.

Q:The speed difference between two rubber rollers is too big.

A:Control the appropriate line speed difference at 5-6 m/s.

300-400 kg/h Spelt Dehuller Machine Working Video

Technical Data

| Model | LG-QLG1 |

| Voltage(V) | 220 |

| Power(kw) | 2.2 |

| Weight(kg/h) | 300-400 |

| Dimension(mm) | 510*510*1020 |

| Weight(kg) | 110 |

Related Products