Large Scale Nut Shredder Machine for Peanut Walnut

- Material: Peanuts, Walnuts, Almonds, Nuts

- Capacity: 500 KG Per Hour

- Loading Port:Qingdao Port

- Warranty:12 Months

- Quote Form:FOB, CIF, EXW, CFR

Features

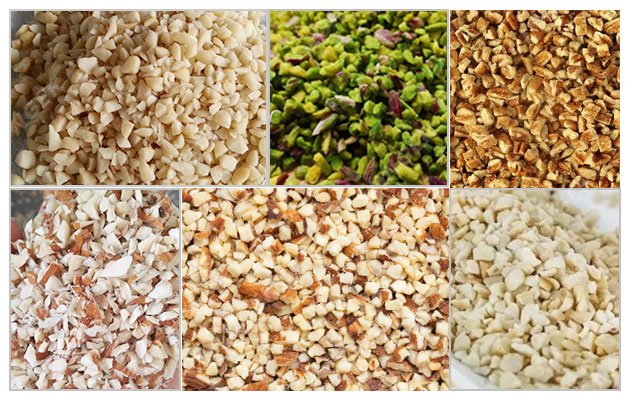

This large nut shredder machine is the perfect solution for shredding all kinds of nuts, with a capacity of up to 500 kg/h, efficient and reliable. It can quickly chop peanuts, walnuts, almonds, and hazelnuts of different sizes, and divide the particles into multiple sizes according to specifications.

Structure of Larege Scale Peanut Shredder Machine

The whole set of equipment is composed of elevator, shredder and screening machine. Each device operates independently and is controlled separately. The main structure of the shredder is composed of a hopper, a hob shredding mechanism, a conveyor belt, and 2 sets of reciprocating straight knife shredding mechanisms.

The design of the machine ensures that the materials are efficiently shredded, and the shredded materials are vibrated and classified to obtain particles of different sizes.

Cutting Process of Nut Shredder Machine

The material enters from the hopper, and then enters the hob cutting mechanism to be roughly cut into large particles quickly. The large particles are sent to two sets of reciprocating shredding mechanisms by the conveyor belt for shredding. The cutted granules are then sieved by a vibrating sieving machine to obtain granules of the required specifications.

Features of Industrial Walnut Shredder Machine

Precautions for Automatic Peanut Shredder Machine:

1. Frequently check whether each transmission part is short of oil, please deal with it in time.

2. Whether the chopper is parallel to the belt bottom plate, and whether the gap size is consistent.

3. If the slider of the cutter is loose, fill it with oil in time.

4. Check whether the lifting conveyor belt deviates, adjust the bolts on both sides to ensure normal operation.

5. The peanut materials to be cut should not have stones and sundries to prevent damage to the conveyor belt and cutter.

Structure of Larege Scale Peanut Shredder Machine

The whole set of equipment is composed of elevator, shredder and screening machine. Each device operates independently and is controlled separately. The main structure of the shredder is composed of a hopper, a hob shredding mechanism, a conveyor belt, and 2 sets of reciprocating straight knife shredding mechanisms.

The design of the machine ensures that the materials are efficiently shredded, and the shredded materials are vibrated and classified to obtain particles of different sizes.

Cutting Process of Nut Shredder Machine

The material enters from the hopper, and then enters the hob cutting mechanism to be roughly cut into large particles quickly. The large particles are sent to two sets of reciprocating shredding mechanisms by the conveyor belt for shredding. The cutted granules are then sieved by a vibrating sieving machine to obtain granules of the required specifications.

Features of Industrial Walnut Shredder Machine

- You can quickly adjust the particle size. The size of the particles is controlled by the speed of the conveyor belt. If the speed is high, the particles will be large, and if the speed is slow, the particles will be small.

- Adjusting the gap between the cutting rollers of the hob can control the coarse particle size of the material, and the appropriate coarse particle size can greatly improve the shredding efficiency.

- The reciprocating speed of the cutter is constant to ensure that the size of the cut material is uniform.

- The vibratory classifying mechanism ensures that the cut particles are precisely and efficiently classified into multiple classes, resulting in a high-quality end product.

- The nut shredding machine can be applied to different nuts, including peanuts, cashews, almonds, pistachios, walnuts, etc., allowing you to use it flexibly to meet various food processing needs.

- Most of the machine is made of high-quality stainless steel to ensure its durability.

- Stable performance, easy operation and labor saving.

Precautions for Automatic Peanut Shredder Machine:

1. Frequently check whether each transmission part is short of oil, please deal with it in time.

2. Whether the chopper is parallel to the belt bottom plate, and whether the gap size is consistent.

3. If the slider of the cutter is loose, fill it with oil in time.

4. Check whether the lifting conveyor belt deviates, adjust the bolts on both sides to ensure normal operation.

5. The peanut materials to be cut should not have stones and sundries to prevent damage to the conveyor belt and cutter.

Technical Data

| Model | LFM-100 |

| Capacity | 400-500kg/h |

| Power | 6kw |

| Dimension | 8000*1500*3000mm |

Related Products