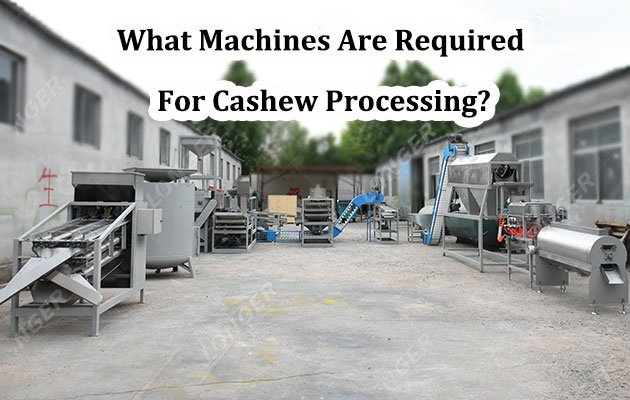

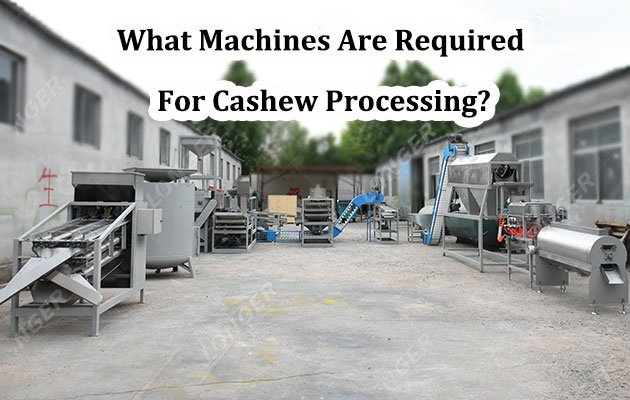

What Machines Are Required For Cashew Processing?

Jul13, 2023

Jul13, 2023

By Serena

By Serena

Cashew processing is a crucial stage in the transformation of raw cashew nuts into the edible and marketable form that we commonly enjoy. This intricate process involves a series of steps that require specific machinery and equipment to ensure efficiency, quality, and safety. So, what machines are required for cashew processing? In this article, we'll introduce some basic machines and understand their role in optimizing production.

1. Cashew Nut Shelling Machine:

1. Cashew Nut Shelling Machine:

The first step in cashew processing is the removal of the outer shell, which encases the precious cashew kernel. Cashew nut shelling machines are designed to mechanically crack the shells without damaging the kernel. These machines employ various techniques such as rotating blades or pneumatic pressure to achieve efficient shelling. They are available in different capacities, from semi-automatic equipment to large-scale automated systems, to meet the needs of many production scales.

2. Cashew Kernel Drying Machine:

2. Cashew Kernel Drying Machine:

After shelling, cashew kernels retain moisture, which must be removed to ensure longer shelf life and prevent mold or fungal growth. Cashew kernel drying machines utilize controlled heat and airflow to reduce the moisture content of the kernels. They are typically equipped with temperature and humidity controls to ensure optimal drying conditions. Proper drying also enhances the flavor and texture of the cashew kernels.

3. Cashew Kernel Grading Machine:

3. Cashew Kernel Grading Machine:

Cashew kernels come in various sizes, and grading them according to size is essential for uniformity in packaging and presentation. Cashew kernel grading machines employ sieves or vibrating screens to separate the kernels into different size categories. This enables producers to cater to specific market demands and offer consistent quality to consumers. Grading machines can be adjusted to accommodate different size ranges and are often equipped with multiple sieves for precise classification.

4. Cashew Kernel Peeling Machine:

4. Cashew Kernel Peeling Machine:

For certain cashew products such as roasted or flavored cashews, the removal of the thin outer skin or testa is necessary. Cashew kernel peeling machines employ mechanical friction or gentle abrasive methods to separate the testa from the kernels. These machines can process large quantities of cashew kernels quickly, reducing manual labor and improving overall productivity.

5. Cashew Kernel Sorting Machine:

5. Cashew Kernel Sorting Machine:

To ensure the highest quality standards, cashew kernel sorting machines are employed to detect and remove any defective or undesirable kernels. Using advanced optical sensors and imaging technology, these machines inspect the color, shape, size, and surface texture of cashew kernels. Any defective kernels are automatically rejected or sorted out, while the acceptable ones continue down the production line.

6. Cashew Nut Packing Machine:

6. Cashew Nut Packing Machine:

Packaging plays a vital role in preserving the freshness and extending the shelf life of cashew products. Cashew nut packing machines automate the packaging process by efficiently filling and sealing the cashews in pouches, bags, or containers. These machines are equipped with weighing scales, volumetric fillers, or counting mechanisms to ensure accurate portioning. They can handle various packaging materials, such as plastic bags, vacuum-sealed packs, or tin containers, depending on the specific product requirements.

Conclusion:

Conclusion:

The cashew processing industry heavily relies on specialized machinery to streamline the complex processes involved in transforming raw cashew nuts into market-ready products. Each machine plays a vital role in enhancing productivity, maintaining quality standards, and optimizing efficiency. By utilizing the appropriate Cashew Nut Processing Machines, producers can ensure consistent output, minimize manual labor, and meet the ever-growing demands of the cashew market. Embracing technology and investing in modern equipment is key to achieving success in this dynamic industry.

Contact Us:

Email: serena@machinehall.com

WhatsApp/Mobile: +8615515597212

Prev:

Prev: