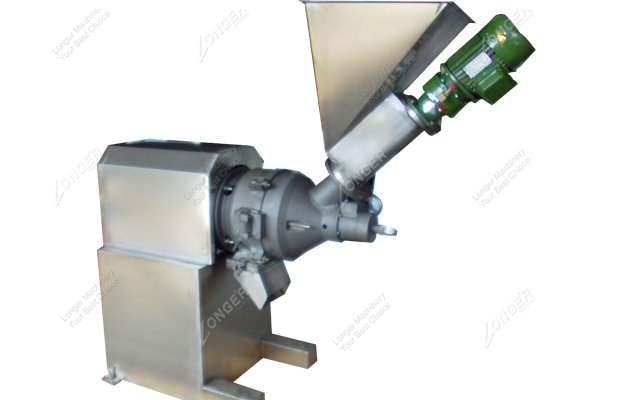

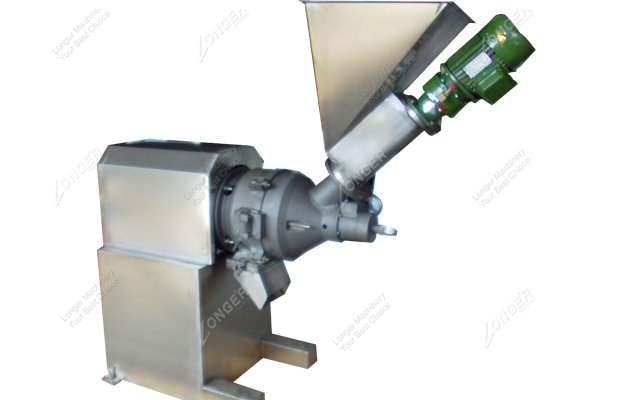

Development Trend of Superfine Grinding Machine

Aug21, 2017

Aug21, 2017

By Serena

By Serena

The existing mill grinding machine,especially superfine grinder fineness and the generation of old products has been greatly improved, the production of a generation of pre research generation is many large enterprises practice at present, facing the development of the ultra mill industry like a raging fire, how to step ahead to lead the development trend is an issue to us the following, we use a more bold to explore the possibilities of the future development trend, ultra mill nanometer pulverizer and the emergence of technical difficulties faced.

In the existing method, obtains the main technique medicinal superfine powder is still mechanical crushing, rely on mechanical method for preparing ultrafine powder superfine crushing and grading skills difficulty increasing, the research depth of world without end. Medical superfine grinding machine is a generalization of many skills, and its development depends on the progress of related skills, such as the processing of Gao Yinggao's tough wear-resistant components, high-speed bearings, submicron particle size distribution measurement, etc.. Therefore, superfine crushing machinery should carry out gathering in the following aspects.

(1) developing precision classification equipment and other necessary equipment matched with superfine grinding equipment. The closed circuit skills associated with ultra fine grinding machines and grading equipment can increase production power, reduce energy consumption, and ensure the quality of qualified products. Can say, large quantity, high precision classification equipment is the key skills of superfine grinding. More research and development should be carried out from the point of view of the whole technical system. On the basis of the existing crushing equipment, we should improve, support and perfect other auxiliary skills and equipment, such as classification equipment, commodity delivery equipment, etc..

(2) grinding machines increase power, decrease energy consumption, and continuously improve and improve superfine grinding equipment. The key of superfine grinding machinery is equipment, therefore, first of all to the development of new superfine crushing equipment and grading of relevant equipment, the latter seems more urgent. Grinding aids and surface active agents will be used in superfine grinding.

(3) integration of equipment and skills research and development. Ultrafine grinding and classification equipment, it is necessary to be accustomed to detailed material characteristics and product goals, specifications, models diversification, without the existence of any material are efficient, omnipotent ultra-fine grinding and classification equipment.

(4) develop multi-functional superfine grinding and surface modification equipment. Such as superfine grinding and boring process, superfine grinding and appearance modification, mechanical force chemistry principle and superfine grinding skills linked, can expand the use of ultra-fine grinding skills scale. Some new materials with common function can be prepared by means of surface coating and solid state miscible dissolution.

(5) development research and superfine grinding skills related to particle size detection and manipulation skills. The particle size detection and manipulation skills of superfine grinding is one of the important conditions for the industrialization and continuous production of ultrafine powders. Particle size testing instruments and measuring manipulation skills are closely related to superfine destructive skills, and it is necessary to tackle them with the professors in these fields.

Prev:

Prev: