Peanut Butter Manufacturing Process in a Factory

Sep30, 2022

Sep30, 2022

By Serena

By Serena

Peanut butter is mainly divided into two categories: sweet and salty. It is rich in aroma, delicate in quality and rich in nutrition. It is a well-deserved healthy food. The wildly popular peanut butter means a huge market. At present, most of the peanut butter sold on the market is mechanized in the factory. The production efficiency is higher, and the processing flow is safer and more hygienic. Next, let's take a look at the peanut butter manufacturing process in a factory.

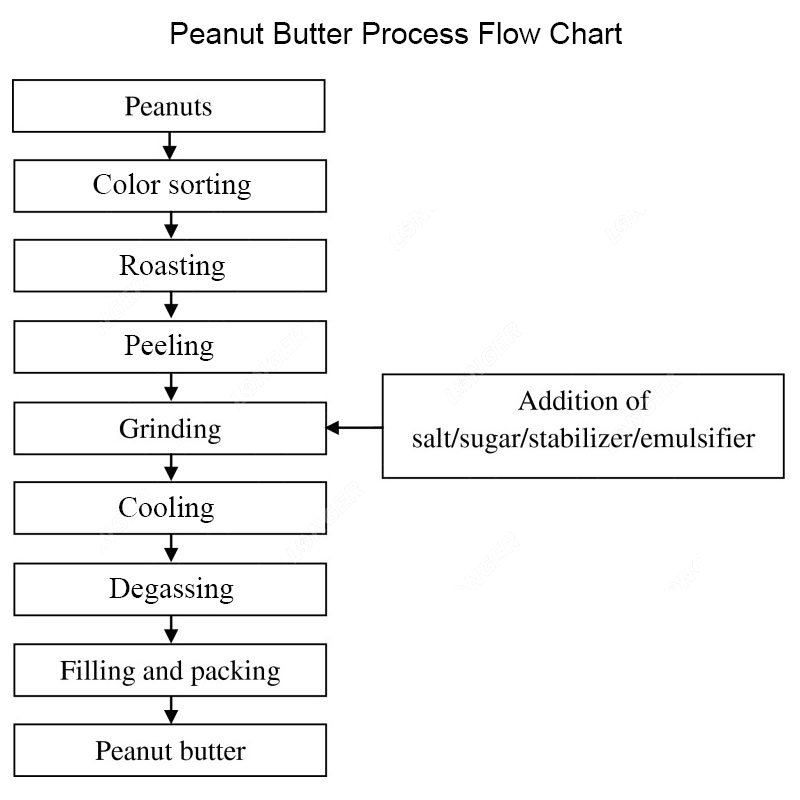

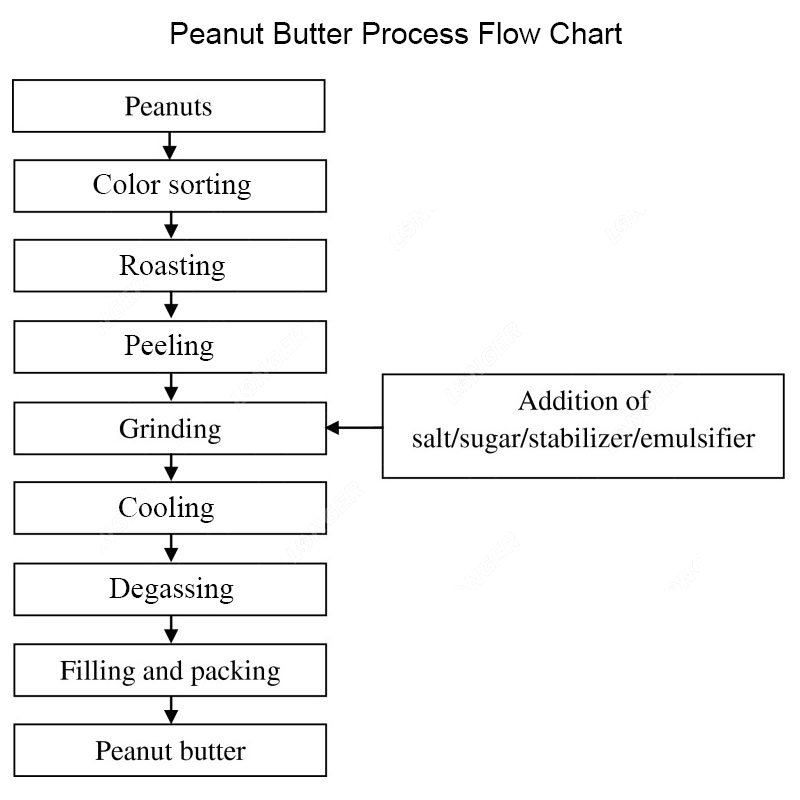

Peanut Butter Processing Flow:

Peanut seeds - stone removal - color sorting - roasting - cooling - peeling - picking - coarse grinding - fine grinding - cooling - degassing - filling peanut butter

Complete Peanut Butter Manufacturing Process

1. Removing stones and impurities

Separation of side-by-side stones, sand, leaves, and other impurities to ensure the normal operation of subsequent processing equipment without damaging the machine.

2. Color selection

Through the color sorter, the peanuts such as mildew and insects are removed in time, and the peanuts exceeding the standard of aflatoxin are quickly and accurately screened, so that the finished peanut butter meets the standard. Selected peanuts with full grain and normal smell.

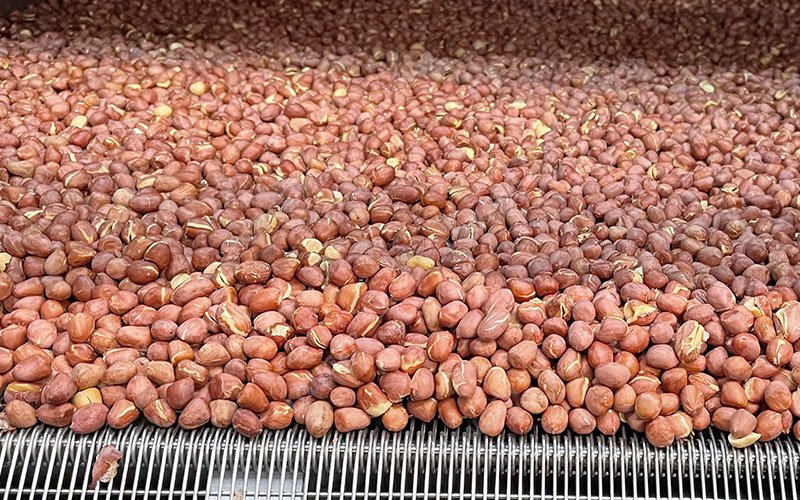

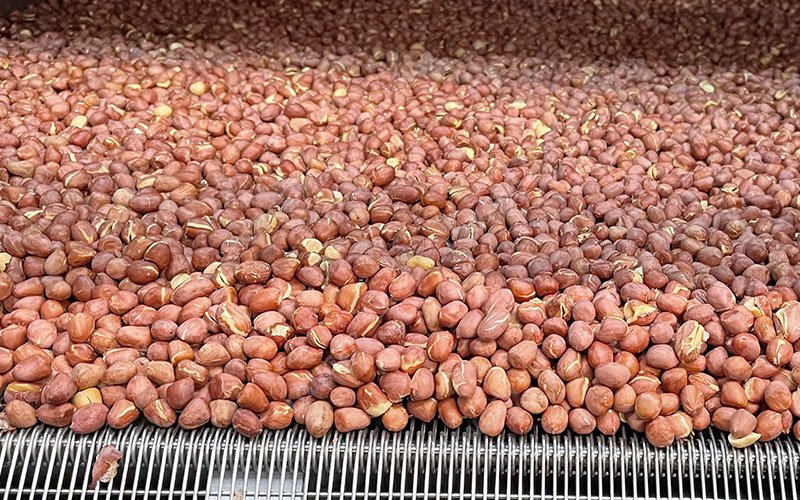

3. Roasting

The peanuts are roasted by drum roasting equipment or continuous roasting equipment, the roasting temperature is 180℃-200℃, and the roasting time is 30-40 minutes. The ideal state of roasting: the peanut kernels are uniform in color, fully cooked and free of scorching.

4. Cooling, peeling

The roasted peanuts are cooled by a fan. After cooling, the outer skin of peanuts can be removed by rubbing lightly. Use a professional half-peeling machine to remove the red coat of the peanuts, and the peanut kernels are crushed into granules, which is more convenient for the subsequent grinding process.

5. Coarse grinding, fine grinding

Coarse grinding is carried out first, and the added accessories are melted by heating up in the coarse grinding, and then the peanut butter grinder is used for fine grinding, and finally the peanut butter is fine and smooth.

6. Cooling down

The special sauce cooler can quickly cool down the peanut butter and prevent the color composition of the sauce from changing due to long-term high temperature, which will affect the appearance and taste.

7. Degassing

Vacuum degassing tanks are usually used to vacuum degas the sauce body, thereby inhibiting browning, oxidation of pigments, vitamins, aroma components and other substances, preventing the quality of peanut butter from being degraded. In addition, degassing also reduces foaming during autoclaving and filling, improving sterilization.

8. Filling

Sterilize the bottle for 20 minutes before filling. Using a special sauce filling machine, the measurement is accurate, the filling volume is adjustable, and the filling temperature is between 10 °C - 20 °C.

Peanut Butter Manufacturing Process Video

The above is the process of making peanut butter in a factory, I hope it will help your business.

Our company can provide you with a fully automatic peanut butter production line according to your needs, as well as a series of professional services including factory planning, production flow chart equipment, equipment research and development, installation and commissioning, daily maintenance, etc., to provide you with competitive investment options .

If you are interested in setting up a peanut butter manufacturing plant, you are welcome to leave your request in the form below to get the exclusive peanut butter processing solution.

Peanut Butter Processing Flow:

Peanut seeds - stone removal - color sorting - roasting - cooling - peeling - picking - coarse grinding - fine grinding - cooling - degassing - filling peanut butter

Complete Peanut Butter Manufacturing Process

1. Removing stones and impurities

Separation of side-by-side stones, sand, leaves, and other impurities to ensure the normal operation of subsequent processing equipment without damaging the machine.

2. Color selection

Through the color sorter, the peanuts such as mildew and insects are removed in time, and the peanuts exceeding the standard of aflatoxin are quickly and accurately screened, so that the finished peanut butter meets the standard. Selected peanuts with full grain and normal smell.

3. Roasting

The peanuts are roasted by drum roasting equipment or continuous roasting equipment, the roasting temperature is 180℃-200℃, and the roasting time is 30-40 minutes. The ideal state of roasting: the peanut kernels are uniform in color, fully cooked and free of scorching.

4. Cooling, peeling

The roasted peanuts are cooled by a fan. After cooling, the outer skin of peanuts can be removed by rubbing lightly. Use a professional half-peeling machine to remove the red coat of the peanuts, and the peanut kernels are crushed into granules, which is more convenient for the subsequent grinding process.

5. Coarse grinding, fine grinding

Coarse grinding is carried out first, and the added accessories are melted by heating up in the coarse grinding, and then the peanut butter grinder is used for fine grinding, and finally the peanut butter is fine and smooth.

6. Cooling down

The special sauce cooler can quickly cool down the peanut butter and prevent the color composition of the sauce from changing due to long-term high temperature, which will affect the appearance and taste.

7. Degassing

Vacuum degassing tanks are usually used to vacuum degas the sauce body, thereby inhibiting browning, oxidation of pigments, vitamins, aroma components and other substances, preventing the quality of peanut butter from being degraded. In addition, degassing also reduces foaming during autoclaving and filling, improving sterilization.

8. Filling

Sterilize the bottle for 20 minutes before filling. Using a special sauce filling machine, the measurement is accurate, the filling volume is adjustable, and the filling temperature is between 10 °C - 20 °C.

Peanut Butter Manufacturing Process Video

The above is the process of making peanut butter in a factory, I hope it will help your business.

Our company can provide you with a fully automatic peanut butter production line according to your needs, as well as a series of professional services including factory planning, production flow chart equipment, equipment research and development, installation and commissioning, daily maintenance, etc., to provide you with competitive investment options .

If you are interested in setting up a peanut butter manufacturing plant, you are welcome to leave your request in the form below to get the exclusive peanut butter processing solution.

Email: serena@machinehall.com

WhatsApp/Mobile: +8615515597212

Prev:

Prev: