How is almond milk made in a factory?

Apr21, 2021

Apr21, 2021

By Serena

By Serena

Almond milk is a milky beverage made from almonds, which is rich in protein and is good for health.

The production process of high-quality almond milk is complicated and requires multiple steps. So how is almond milk made in the factory? Let's see below.

How is Almond Milk Made Commercially?

In business (such as beverage shop, dairy shop, etc.) and at home, the demand for almond milk is generally not big, so the equipment used is blender.

Commercial Almond Milk Production Process:

Commercial Almond Milk Production Process:

- 1. After washing the almonds, pour them into clean water and soak for at least 12 hours. This step can make the almonds easier to break, and can also awaken the enzymes on the surface of the almonds, so that the human body will digest them better. You can soak the almonds at night and make almond milk the next day.

- 2. Pour the almonds into a blender, add 2-3 times the amount of drinking water equivalent to the amount of almonds, and then beat until creamy.

- 3. Filter out the almond residue with gauze to get almond milk. (This step can also be omitted, according to personal preference.)

How is Almond Milk Made In a Factory?

The production of almond milk in the factory is large, in addition, the shelf life will be longer, so the almond milk factory uses a set of professional and complete equipment.

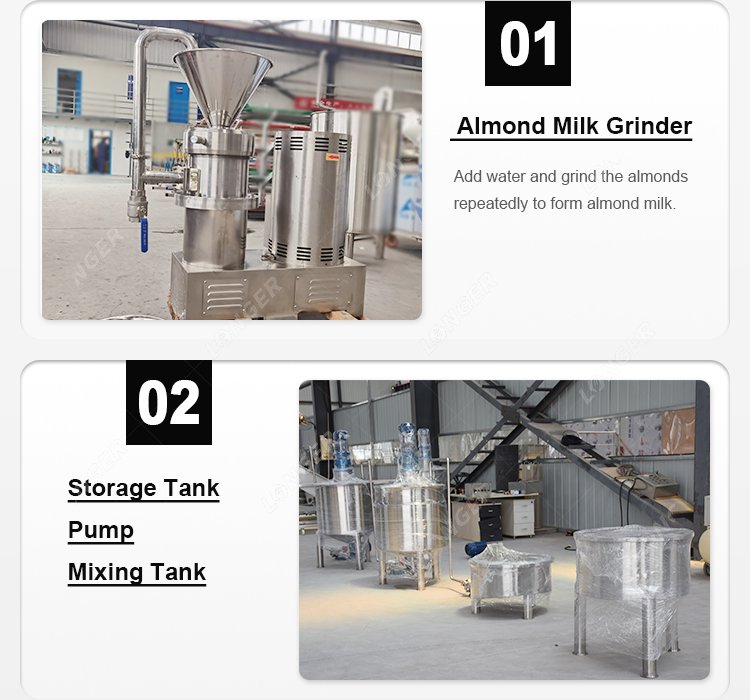

Industrial Almond Milk Manufacturing Process:

Grinding -Storage - Screening and Mixing - Storage - Mixing - Sterilization - Storage - Packing

- 1. Grinding: Use a colloid mill, add water and almonds, and grind in a cycle to make almond milk. The ratio of water to almonds is approximately 10:1.

- 2. Screening and Mixing: filter almond milk through a 200-mesh sieve. (You can add preservatives or additives according to your own processing technology, then mix and grind).

- 3. Sterilization: Sterilize almond milk to ensure food safety and sanitation.

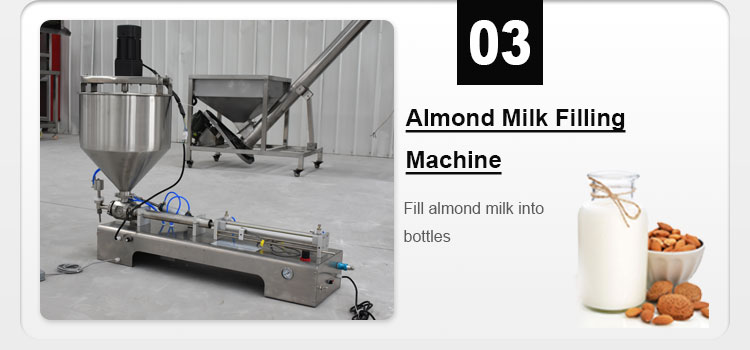

- 4. Filling: Use a filling machine to bottle almond milk and seal it.

In the above process, many professional almond milk processing equipment are used, such as almond peeling machine, almond milk maker machine, sterilizing machine, filling machine and so on. These machines usually are necessary for a almond milk production factory. But sometimes, almonds without peeling can be directly ground into almond milk. Customers can choose the right machine according to their own processing process.

In different almond milk factories, the equipment may be different, depending on the almond milk manufacturing process.

Almond milk is rich in nutrients:

Almond is rich in protein, 18 amino acids, linolenic acid, a variety of vitamins and potassium, calcium, zinc, iron, selenium, iodine and other minerals. Almond is also rich in flavonoids and polyphenols. Not only can it reduce the cholesterol content in the body, but also significantly reduce the risk of heart disease and many chronic diseases.

The above are just a few answers to "How is almond milk produced". If you also want to start producing almond milk, please contact us.

Almond milk is rich in nutrients:

Almond is rich in protein, 18 amino acids, linolenic acid, a variety of vitamins and potassium, calcium, zinc, iron, selenium, iodine and other minerals. Almond is also rich in flavonoids and polyphenols. Not only can it reduce the cholesterol content in the body, but also significantly reduce the risk of heart disease and many chronic diseases.

The above are just a few answers to "How is almond milk produced". If you also want to start producing almond milk, please contact us.

Email: serena@machinehall.com

WhatsApp/Mobile: +8615515597212

Prev:

Prev: