Efficient Melon Seed Cracker| Watermelon Seed Dehulling Machine

- Material: Melon seeds, Watermelon seeds

- Capacity: 200-300 kg/h

- Loading Port:Qingdao Port

- Warranty:12 Months

- Quote Form:FOB, CIF, EXW, CFR

Features

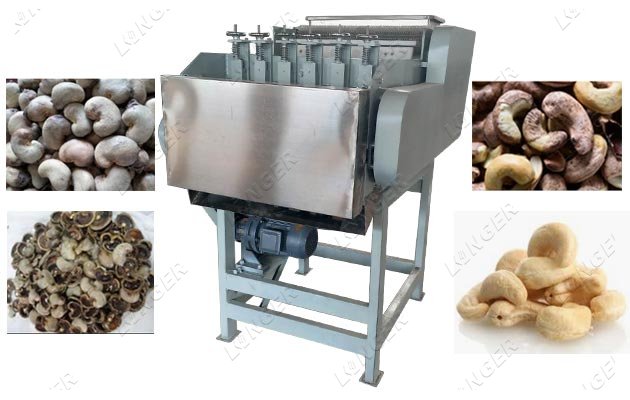

The watermelon seed dehulling machine is a special unit to crack the shells and separate kernels. The machine is also suitable for dehulling white melon seeds, watermelon seeds, pumpkin seeds etc. High shelling rate and high efficiency.

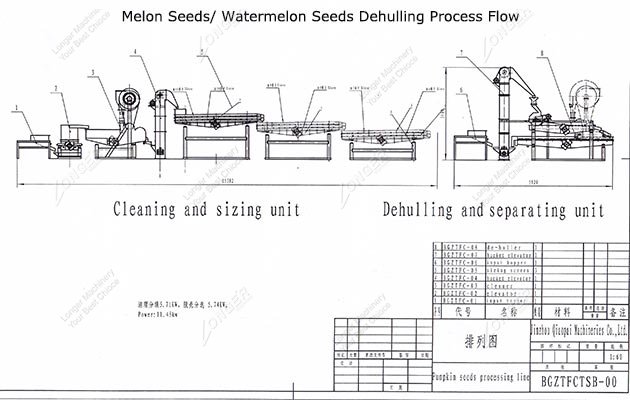

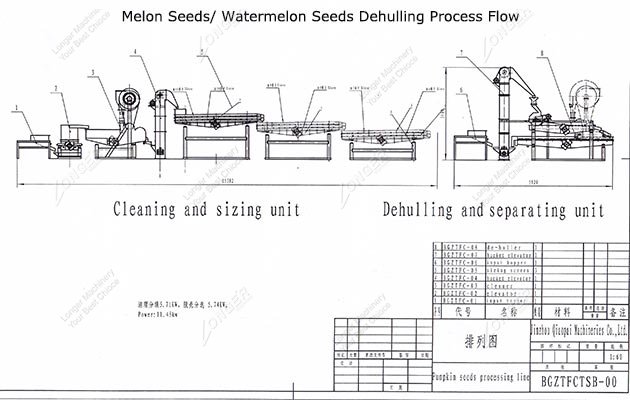

Melon seed dehulling process: Feeding → Lifting → Shelling → Separation of skin kernels → Seed sorting

Advantages of Watermelon Seed Dehulling Machine

The device has the characteristics of low energy consumption, compact structure, small space occupation, low loss of seed kernel, easy operation and maintenance, and the like, and is the best equipment for dehulling and sorting melon seeds.

Working Video of Melon Seed Cracker Machine

Related Product: Pumpkin Seed Shelling Machine

(1) Melon seed cleaning equipment

① upper hopper ② screw elevator ③ multi-function impurity remover ④ bucket elevator ⑤ grading screen (divided into three levels)

(2) Melon seed dehulling machine

① feeding hopper ② raw material elevator

③ main machine (including cracker, husk kernel separator, kernel separator, cyclone separator, screw discharger, etc.)

④ check machine ⑤ suction return system ⑥ centralized control cabinet

Melon seed dehulling process: Feeding → Lifting → Shelling → Separation of skin kernels → Seed sorting

Advantages of Watermelon Seed Dehulling Machine

The device has the characteristics of low energy consumption, compact structure, small space occupation, low loss of seed kernel, easy operation and maintenance, and the like, and is the best equipment for dehulling and sorting melon seeds.

- The unique wind recirculation system allows the unseparated kernels to automatically enter the next shelling cycle, thereby greatly improving the shelling efficiency.

- Different sizes of white melon seeds can be processed by changing the sorting screen section.

- All control appliances are installed in a dedicated electric control cabinet, and all operation buttons are installed on the control panel of the electric control cabinet for easy operation.

Power requirements of watermelon seed cracker machine:

The power supply is three-phase four-wire system, 50 Hz, 380 volts, and the voltage fluctuation does not exceed ±10%. The main circuit voltage is 380 VAC and the control loop voltage is 220 VAC.

Use of the inverter:

The melon seed cracker is controlled by a centralized control cabinet. The frequency converter for adjusting the input parameters of the shelling machine is connected in the main circuit. The parameter setting of the frequency converter has been adjusted before leaving the factory. Do not set it at will (220V). except).

Working Video of Melon Seed Cracker Machine

Technical Data

| Power | 4.42kw (380v/50HZ) |

| Whole Kernel Rate | more than 95% |

| Capacity | 200-300kg/h |

| Space Occupied | 6.2*2.5m |

| Height | 3.2 m |

| Weight | 1.5 t |

| Machine | Quantity |

| Input Hopper | 1 |

| Elevator | 1 |

| Dehuller and Separating | 1 |

| Resorting Sieve Section | 1 |

| Discharge Hopper | 1 |

| Control Cabinet |

Related Products